A term often used when discussing the specifications of different linear actuators is their stroke or stroke length. If this is your first time looking for a linear actuator or you don’t have much of a mechanical background, you may be wondering what stroke refers to and what it means for the linear actuator. This post will hopefully give you a better understanding of what stroke means for different linear actuators and how it can impact your chosen linear actuator. If you are looking to learn more about linear actuators check out our Linear Actuator 101 blog.

What Does Stroke Mean?

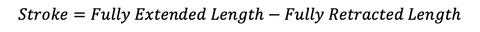

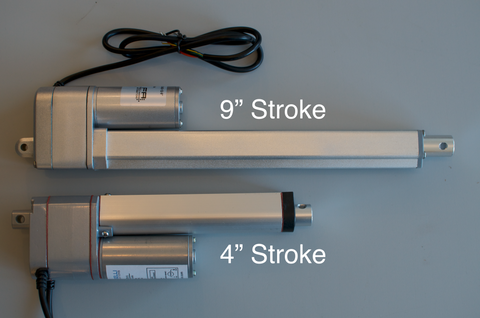

For most linear actuators, stroke or stroke length refers to how far the linear actuator moves and is equal to the fully extended length minus the fully retracted length. Where the fully extended length refers to the total length of the actuator when extended and fully retracted length refers to the total length of the actuator when retracted.

Above shows how to measure the stroke of an Actuator - First when it is closed.

Above shows how to measure the stroke of an Actuator - When it is Open. The difference is the stroke.

For most basic rod linear actuators, the stroke is how far the rod extends outwards from the body of the actuator. For example, if a rod actuator has a stroke of 2”, the rod would extend 2” outwards when fully extended.

Although this is not always the case, especially for track actuators. Track linear actuators don’t use an extending rod to provide linear motion but make use of a sliding carriage that moves along a fixed length track. Because of this, the stroke for these actuators means something slightly different. While it still refers to how far the actuator moves, it is no longer equal to the fully extended length minus the fully retracted length but is simply equal to the length of the track.

What Does Stroke Length Impact?

Choosing different stroke lengths will impact the physical size of your chosen linear actuator. For basic rod actuators, the rod of the linear actuator will need to be long enough to achieve the desired stroke. Because of this, the fully retracted length of the linear actuator will be dependent on the selected stroke length and will be equal to the stroke plus the additional space for the internal components of the actuator; like the motor, gearbox, etc. For track actuators, the total length of the actuator will also depend on the stroke, as the stroke length is the length of the physical track. Like with the fully retracted length of the rod actuators, the length of the track actuator will be equal to stroke plus the additional space for the internal components.

While the above is true for all track actuators and rod actuators, it is not always the case. Lifting columns are a type of actuator that will often use multiple stages of actuation and because of this, will be smaller than their stroke length when fully collapsed. The multiple stages mean the extending components of the actuator are divided into multiple segments rather than one solid rod or track. As these segments can be collapsed inside of each other, this gives the lifting column the ability to be smaller than its designed stroke length while also containing all of the internal actuator components.