How to calculate a 2nd Class lever - try our Calculator below

A second-class lever is a simple machine that consists of a rigid bar that pivots around a fixed point called a fulcrum. The load or weight is located between the fulcrum and the effort or force that is applied to move the load. In other words, the load is farther away from the fulcrum than the effort, and the effort is applied in the opposite direction of the load.

A second-class lever is used to increase the force applied to a load. By positioning the load closer to the fulcrum than the effort, a small force can be applied to the end of the lever, which is amplified as it moves the load farther from the fulcrum. This type of lever is not as common as first-class or third-class levers but can be found in many real-world examples.

To calculate the mechanical advantage of a second-class lever, you need to determine the ratio of the distance from the load to the fulcrum (L) to the distance from the effort to the fulcrum (E). The mechanical advantage (MA) can be expressed as:

MA = L / E

Some real-world examples of second-class levers include:

- Nutcracker: A nutcracker is a common example of a second-class lever. The load is the nut, which is placed between the two arms of the lever, and the effort is applied to the other end of the lever.

- Wheelbarrow: A wheelbarrow is another example of a second-class lever. The load is the weight of the contents in the wheelbarrow, which is positioned between the wheel and the handles. The effort is applied to the handles, which are closer to the fulcrum than the load.

- Bottle opener: A bottle opener is also a second-class lever. The load is the cap on the bottle, and the effort is applied to the other end of the lever, which is closer to the fulcrum.

In summary, a second-class lever is a simple machine that can be used to increase the force applied to a load. They are not as common as other types of levers but can be found in many real-world examples, such as nutcrackers, wheelbarrows, and bottle openers.

Results

Actuator Force Required F:

0 lbs

0 N

0 kg

0 g

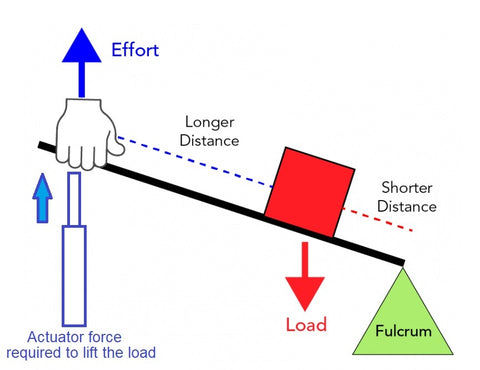

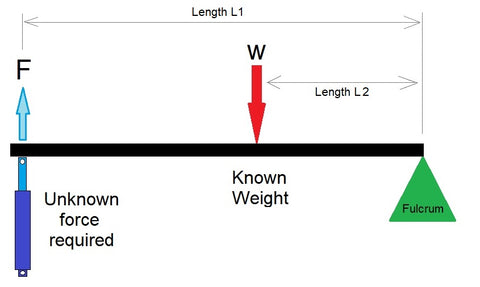

Principle behind the Calculations

In a second-class lever, the load or resistance is located between the fulcrum and the effort. The effort arm is always longer than the load arm. The formula to calculate the effort required in a second-class lever is:

Effort x Effort Arm = Load x Load Arm

where:

- Effort: the force applied to the lever to move the load

- Effort Arm: the distance from the fulcrum to the point where the effort is applied

- Load: the weight or resistance being moved by the lever

- Load Arm: the distance from the fulcrum to the point where the load is applied

To find any of the variables in the equation, the other three variables must be known.

Tonneau Cover Lift uses a 2nd class lever

In the case of a Tonneau cover, where electric actuators are used to lift the cover up and down, then we assume the weight is evenly distributed over the entire length. In this case the load can be treated as a point load acting at the midpoint of the load arm. The midpoint is where the load arm is equal to half the total length of the load arm.

- Effort: the force applied to the lever to move the load

- Effort Arm: the distance from the fulcrum to the point where the effort is applied

- Load: the weight or resistance being moved by the lever

- Load Arm: the distance from the fulcrum to the midpoint of the load arm

How is a 2nd class lever different from a 3rd class lever?

A second-class lever and a third-class lever are different in terms of the arrangement of their three components: effort, load, and fulcrum. Here's a summary of their differences: Second-class lever:- The load is situated between the effort and the fulcrum.

- The effort moves in the opposite direction of the load.

- Second-class levers generally provide a mechanical advantage, meaning the effort required to move the load is less than the force exerted by the load.

- Examples of second-class levers include wheelbarrows, nutcrackers, and bottle openers.

- The effort is located between the fulcrum and the load.

- The effort moves in the same direction as the load.

- Third-class levers typically provide a mechanical disadvantage, meaning the effort required to move the load is greater than the force exerted by the load. However, they often provide a speed and range of motion advantage.

- Examples of third-class levers include tweezers, human limbs (like the biceps acting on the forearm), and a baseball bat held by a batter.

We have created some blog posts on other classes of levers, shortcuts to these are shown below:

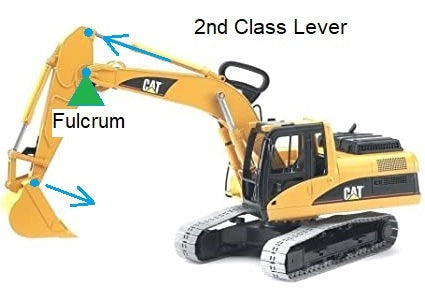

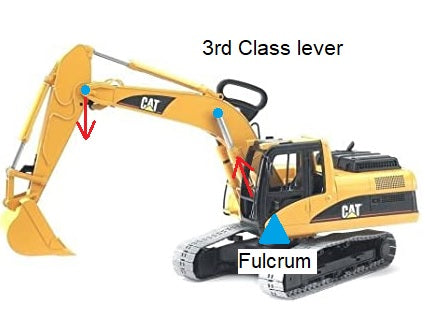

Real world example of a 2nd and 3rd Class lever