Unleashing the Power of Mechanical Advantage: A Complete Exploration of Levers, Pulleys, Gears, Hydraulics, and Beyond

Introduction: Welcome to our in-depth exploration of mechanical advantage mechanisms. In this comprehensive guide, we will delve into the fascinating world of force, speed and distance amplification, leverage, and efficiency. Whether you're a DIY enthusiast, an engineer, or simply curious about how things work, this article will provide you with a wealth of knowledge about the various types of mechanical advantage mechanisms and their applications. Join us as we uncover the secrets behind levers, pulleys, gears, Actuators, and other ingenious devices that make our lives easier.

Table of Contents:

- Understanding Mechanical Advantage

- Levers: Unleashing the Power of Balance and Leverage 2.1 Class 1 Lever 2.2 Class 2 Lever 2.3 Class 3 Lever 2.4 Pros, Cons, and Trade-offs of Levers

- Pulleys: The Art of Load Distribution 3.1 Fixed Pulleys 3.2 Movable Pulleys 3.3 Compound Pulleys 3.4 Pros, Cons, and Trade-offs of Pulleys

- Inclined Planes and Wedges: Conquering Vertical Challenges 4.1 Simple Inclined Plane 4.2 Screw 4.3 Pros, Cons, and Trade-offs of Inclined Planes and Wedges

- Gears: Meshing Precision and Power 5.1 Spur Gears 5.2 Bevel Gears 5.3 Worm Gears 5.4 Pros, Cons, and Trade-offs of Gears

- Actuators: The Advantages 6.1 Pascal's Principle 6.2 Actuator Systems 6.3 Pros, Cons, and Trade-offs of Actuator Systems

- Mechanical Advantage Systems: Force, Distance, and Speed 7.1 Force Advantage Systems 7.2 Distance Advantage Systems 7.3 Speed Advantage Systems 7.4 Pros, Cons, and Trade-offs of Mechanical Advantage Systems

- Conclusion

Section 1: Understanding Mechanical Advantage

Mechanical advantage lies at the heart of many everyday devices and machines, enabling us to accomplish tasks with greater ease and efficiency. Before diving into the specific types of mechanical advantage mechanisms, it's essential to grasp the fundamental concepts and principles that underpin this concept.

1.1 Definition of Mechanical Advantage Mechanical advantage refers to the amplification of force or motion achieved through the use of tools, machines, or systems. It allows us to overcome resistance, lift heavy objects, or accomplish tasks that would be otherwise challenging or impossible without the application of additional force.1.2 The Importance of Mechanical Advantage Understanding mechanical advantage is crucial in various fields, including engineering, physics, and design. By harnessing the power of mechanical advantage, engineers can optimize the performance and efficiency of machines and systems. From simple tools to complex industrial machinery, mechanical advantage plays a vital role in enhancing productivity, reducing physical effort, and conserving energy.

1.3 Leveraging Principles of Physics At its core, mechanical advantage is rooted in the fundamental principles of physics. One such principle is the conservation of energy, which states that energy cannot be created or destroyed but can only be transformed or transferred. Mechanical advantage mechanisms allow us to transform energy from one form to another to accomplish specific tasks more effectively.

1.4 Types of Mechanical Advantage Systems Mechanical advantage systems can be categorized into three main types based on the desired outcome: force advantage, distance advantage, and speed advantage.

- Force Advantage: A force advantage system amplifies the input force to generate a larger output force. This allows us to exert greater force than what is initially applied, enabling the lifting or moving of heavy objects with relative ease. Levers and hydraulic systems are examples of force advantage mechanisms.

- Distance Advantage: A distance advantage system allows us to cover a greater distance or achieve a larger range of motion using a smaller input displacement. These mechanisms provide a mechanical advantage by increasing the output distance or displacement relative to the input. Pulley systems and inclined planes are common examples of distance advantage mechanisms.

- Speed Advantage: In speed advantage systems, the output speed is increased relative to the input speed. This enables tasks to be completed more rapidly by sacrificing force or distance. Gears and certain types of pulley systems can be utilized to achieve a speed advantage.

- Force advantage systems excel in tasks that require lifting heavy objects or exerting significant force. However, they may require more input effort or energy to achieve the desired output force. Additionally, force advantage mechanisms often sacrifice speed or distance in favor of force amplification.

- Distance advantage systems allow for increased range of motion or displacement using a smaller input force. They are suitable for tasks that involve moving objects over a greater distance. However, distance advantage mechanisms may require increased input effort or a longer input displacement.

Above see how a Telescopic Actuator can be created using pulleys and leadscrew drive

- Speed advantage systems are ideal for tasks that prioritize speed or rapid motion. They can accomplish tasks quickly but may sacrifice force or distance. Speed advantage mechanisms are commonly used in applications such as machinery with rotating components or transportation systems.

Above video shows how a Telescopic Linear Actuator (Column Lift is made)

Understanding the pros, cons, and trade-offs of each type of mechanical advantage system is crucial for selecting the most appropriate mechanism for a given task or application.

By grasping the fundamental principles and types of mechanical advantage systems, you can unlock the potential to optimize performance, improve efficiency, and achieve remarkable feats with less effort. In the following sections, we will delve deeper into specific mechanical advantage mechanisms, including levers, pulleys, gears, hydraulics, and more, exploring their mechanisms, applications, and further insights into the advantages and trade-offs they offer.

Section 2: Exploring Mechanical Advantage Mechanisms

In this section, we will explore various mechanical advantage mechanisms that leverage the principles of force, distance, and speed advantage. These mechanisms enable us to achieve enhanced performance and efficiency in different applications. Let's dive into each mechanism in detail:

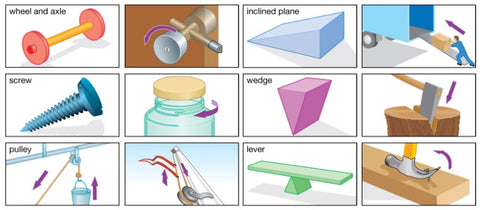

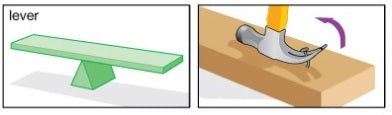

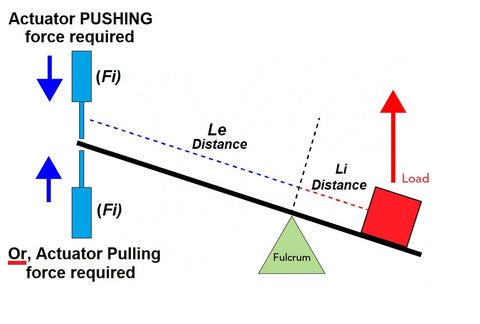

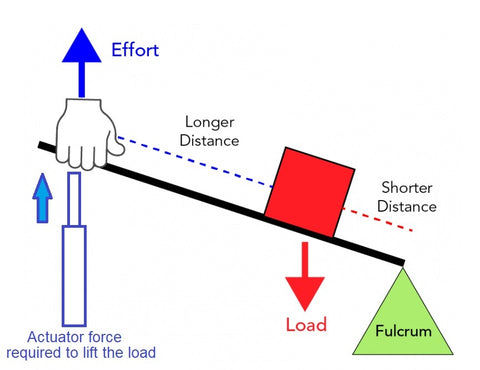

2.1 Levers Levers are one of the most fundamental mechanical advantage mechanisms, consisting of a rigid bar or beam pivoting around a fixed point called the fulcrum. They are classified into three types based on the relative positions of the fulcrum, input force (effort), and output force (load): first-class levers, second-class levers, and third-class levers.

Try our First class Lever online calculator above

- Second-Class Levers: In a second-class lever, the fulcrum is positioned at one end, while the output force is at the opposite end. The input force is applied between the fulcrum and the output force. Second-class levers provide a significant force advantage, making them suitable for tasks that involve lifting heavy loads. A classic example of a second-class lever is a wheelbarrow.

- Third-Class Levers: In a third-class lever, the fulcrum is positioned at one end, and the input force is applied at the opposite end. The output force is located between the fulcrum and the input force. Third-class levers offer a distance advantage, enabling increased range of motion or displacement. Examples of third-class levers include tweezers and fishing rods.

![]() Try our Third class Lever online calculator above

Try our Third class Lever online calculator above

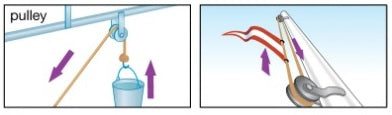

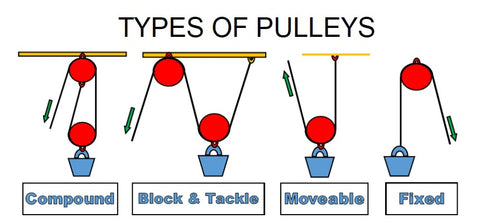

2.2 Pulleys Pulleys are mechanical devices that consist of a grooved wheel and a cable or rope. They are designed to change the direction of the applied force and provide mechanical advantage in terms of force or distance.

- Fixed Pulleys: A fixed pulley is anchored to a structure, and the rope or cable passes over the wheel. The effort applied to the rope results in an equal and opposite force in the load. Fixed pulleys do not provide a mechanical advantage in terms of force, but they change the direction of the force, making it more convenient to move objects vertically or horizontally.

- Movable Pulleys: In a movable pulley, one end of the rope is fixed, while the pulley itself moves with the load. This arrangement effectively halves the force required to lift the load, providing a force advantage. Movable pulleys are commonly used in cranes and block-and-tackle systems.

- Compound Pulleys: Compound pulleys combine fixed and movable pulleys to provide even greater mechanical advantage. They involve multiple pulleys attached to different fixed and movable points, allowing for increased force advantage. Compound pulleys are often found in complex lifting systems and machinery.

- Spur Gears: Spur gears have straight teeth and are the most common type of gears. They transmit motion and power between parallel shafts, offering precise control over speed and torque. Spur gears can provide both speed and force advantage depending on their size and arrangement.

- Helical Gears: Helical gears have angled teeth that are arranged in a helix pattern. This design allows for smoother and quieter operation compared to spur gears. Helical gears excel in transmitting power between parallel shafts, providing a balance between speed and force advantage.

- Worm Gears: Worm gears consist of a threaded shaft (worm) that meshes with a toothed wheel (worm gear). They offer a high gear ratio and are commonly used in applications that require high torque and low speed, such as lifting mechanisms and conveyor systems.

- Hydraulic Pistons: Hydraulic pistons are cylinders that contain a fluid and a movable piston. When force is applied to one end of the piston, it creates pressure in the fluid, transmitting the force to the other end. Hydraulic pistons provide significant force advantage and are commonly used in applications such as automotive braking systems and construction machinery.

- Hydraulic Presses: Hydraulic presses utilize hydraulic pistons to amplify force for tasks such as pressing, punching, or shaping materials. By applying a small force to a small piston area, a larger force can be generated at a larger piston area, providing a substantial force advantage.

- Hydraulic Lifts: Hydraulic lifts are widely used in automotive repair shops, elevators, and other applications where heavy objects need to be raised or lowered. By utilizing hydraulic pistons and the principle of force advantage, hydraulic lifts can effortlessly handle substantial loads with relative ease.

Section 3: Types of Mechanical Advantage Systems

In this section, we will delve into the three types of mechanical advantage systems: force advantage, distance advantage, and speed advantage. Each system offers unique benefits and trade-offs, depending on the specific requirements of the application. Let's explore each system in detail:

3.1 Force Advantage Systems Force advantage systems focus on amplifying the force applied to overcome resistance or lift heavy loads. These systems allow users to exert a greater force than what they could generate on their own. Here are some notable force advantage mechanisms:- Levers: Levers, especially second-class and third-class levers, provide force advantage by amplifying the applied force to lift or move heavy objects. The longer the lever arm or the closer the load is to the fulcrum, the greater the force advantage.

- Pulleys: Movable pulleys and compound pulley systems increase force advantage by distributing the load across multiple ropes and pulleys. This allows for a significant reduction in the force required to lift or move heavy objects.

- Hydraulic Systems: Hydraulic systems utilize the incompressibility of fluids to amplify force. By applying a small force to a small piston area, the system generates a larger force at a larger piston area, providing substantial force advantage.

Force advantage systems are ideal for applications that involve heavy lifting, such as construction, manufacturing, and transportation. They enable users to overcome resistance with less effort and achieve efficient and controlled force application.

3.2 Distance Advantage Systems Distance advantage systems focus on increasing the range of motion or displacement of an object with the same input force. These systems are particularly useful in applications where the emphasis is on covering a larger distance or achieving greater displacement. Let's explore some distance advantage mechanisms:

- Levers: Third-class levers, by positioning the input force closer to the fulcrum and the output force farther away, provide a significant distance advantage. They allow for greater range of motion or displacement with the same input force.

- Gears: Gears with different sizes and arrangements can be used to achieve distance advantage. Larger gears driving smaller gears result in increased rotational speed and range of motion.

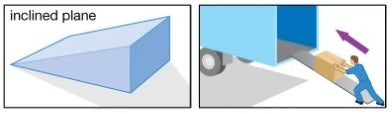

- Inclined Planes: Inclined planes, such as ramps, allow objects to be moved over longer distances with less effort. By increasing the distance traveled along the plane, the input force is distributed over a larger distance, achieving a distance advantage.

Distance advantage systems find applications in scenarios where extended motion or displacement is crucial. They are commonly employed in fields such as construction, transportation, and sports, where achieving a greater range or distance is desired.

3.3 Speed Advantage Systems Speed advantage systems focus on increasing the speed or velocity of an object while maintaining a balanced force. These systems are valuable in applications where swift movement or rapid operations are necessary. Let's explore some speed advantage mechanisms:- Gears: Gears with different sizes and arrangements can be used to achieve speed advantage. Smaller gears driving larger gears result in increased rotational speed while reducing the force output.

- Pulleys: Fixed pulleys can provide speed advantage by changing the direction of motion, allowing for faster movement in a desired direction. However, speed advantage is achieved at the expense of force advantage.

- Mechanical Linkages: Mechanical linkages, such as crank-rocker mechanisms or cam-follower systems, can convert rotary motion into linear motion, enabling high-speed operations.

Speed advantage systems are commonly found in industries such as automation, robotics, and manufacturing, where fast and efficient operations are required. They enable rapid movement and increase overall productivity.

Understanding the different types of mechanical advantage systems empowers engineers, designers, and enthusiasts to optimize their designs and applications for specific requirements. By leveraging force advantage, distance advantage, or speed advantage, they can achieve desired outcomes efficiently while considering the trade-offs associated with each system.

In the next section, we will explore additional mechanical advantage mechanisms, including inclined planes, wedges, and screws, and discuss their practical applications and considerations.

Section 4: Practical Applications and Considerations of Mechanical Advantage Mechanisms

In this section, we will explore practical applications of mechanical advantage mechanisms and discuss important considerations when implementing them in various scenarios. Understanding these applications and considerations will help you make informed decisions when selecting and utilizing mechanical advantage systems. Let's dive in:

4.1 Levers: Levers are versatile mechanical advantage mechanisms widely used in various applications. They can be found in seesaws, crowbars, scissors, and even the human body. Levers are classified into three classes based on the position of the fulcrum, load, and effort. Some common applications and considerations of levers include:- First-class levers: have the fulcrum positioned between the load and the effort. Examples include scissors and seesaws. When using first-class levers, it's important to consider the balance between the effort and the load to ensure optimal performance.

- Second-Class Levers: Second-class levers have the load positioned between the fulcrum and the effort. Examples include wheelbarrows and bottle openers. When using second-class levers, consider the positioning of the load to maximize force advantage.

- Third-Class Levers: Third-class levers have the effort positioned between the fulcrum and the load. Examples include tweezers and fishing rods. Third-class levers are commonly used when the emphasis is on achieving a greater range of motion or displacement.

When employing levers, factors such as the length of the lever arm, the position of the load and effort, and the balance between force and distance advantage should be taken into account for optimal performance.

4.2 Pulleys: Pulleys are mechanical devices that use grooved wheels and ropes or cables to achieve mechanical advantage. They are widely used in lifting systems, cranes, elevators, and various industrial applications. Some important considerations and applications of pulleys include:

- Fixed Pulleys: Fixed pulleys change the direction of force without providing any mechanical advantage. They are often used to redirect forces or change the direction of motion in systems. When implementing fixed pulleys, consider the smoothness of operation and the compatibility of the pulley material with the load.

- Movable Pulleys: Movable pulleys are attached to the load and provide force advantage by distributing the load between multiple ropes. They are commonly used in block and tackle systems. Consider the load distribution, rope strength, and the number of pulleys required for efficient load lifting.

- Compound Pulleys: Compound pulleys combine fixed and movable pulleys to achieve a higher degree of mechanical advantage. They offer increased force advantage but require longer rope lengths. When using compound pulleys, consider the complexity of the system and the space required for the extended rope length.

Proper maintenance of pulleys, regular inspection of ropes or cables, and ensuring smooth operation are crucial factors to ensure the safety and efficiency of pulley systems.

4.3 Inclined Planes: Inclined planes are simple yet effective mechanical advantage mechanisms used in various applications, such as ramps, staircases, and slides. They reduce the amount of force required to move objects vertically by increasing the distance traveled along the plane. Considerations and applications of inclined planes include:- Load Weight Distribution: When using inclined planes, consider the weight distribution of the load to ensure stability and prevent accidents. Proper friction between the load and the plane surface should be maintained to avoid slipping or sliding.

- Angle of Inclination: The angle of inclination affects the mechanical advantage of the inclined plane. Shallower angles require less force but cover longer distances, while steeper angles require more force but cover shorter distances. Choose the appropriate angle based on the specific application requirements.

- Friction: Friction plays a crucial role in the efficiency of inclined planes. Consider the type of surface material, lubrication, and the presence of external factors like moisture or debris that may affect the friction between the load and the plane.

By understanding the load characteristics, angle of inclination, and friction considerations, you can effectively utilize inclined planes to reduce the force required for lifting or moving objects.

4.4 Wedges: Wedges are mechanical advantage mechanisms with a sharp edge used for splitting, cutting, or holding objects in place. They can be found in tools like knives, axes, and chisels. Considerations and applications of wedges include:

- Material Selection: The material used for wedges is important to ensure durability and effective splitting or cutting. Consider the hardness, strength, and sharpness of the wedge material based on the specific application requirements.

- Angle and Force Application: The angle at which the wedge is driven into an object affects the splitting or cutting efficiency. The force applied and the angle of the wedge should be balanced to achieve the desired outcome without damaging the object or the wedge.

- Safety Considerations: When using wedges, it's essential to follow proper safety procedures to prevent accidents. Adequate protective gear, stable work surfaces, and proper handling techniques should be employed to ensure personal safety.

Understanding the properties and application techniques of wedges will enable you to choose the right tool and employ effective methods for splitting, cutting, or securing objects.

4.5 Screws: Screws are widely used mechanical advantage mechanisms that convert rotational motion into linear motion. They are utilized in applications ranging from woodworking to robotics. Considerations and applications of screws include:

- Pitch and Thread Design: The pitch and thread design of screws play a vital role in determining the mechanical advantage and the amount of force required. Coarse threads provide greater mechanical advantage but require more rotational force, while fine threads offer increased precision but lower mechanical advantage.

- Torque and Turning Direction: Screws require torque to move linearly. Understanding the relationship between torque, rotational force, and linear displacement is important for achieving the desired mechanical advantage. Consider the appropriate turning direction and the torque required for the specific application.

- Material Compatibility: Screws are available in various materials, including steel, stainless steel, and brass. Consider the environmental conditions, load requirements, and material compatibility when selecting the right screw for your application.

Proper alignment, regular maintenance, and choosing the correct screw type and size based on the load requirements are crucial for achieving optimal performance and durability.

By understanding the practical applications and considerations of these mechanical advantage mechanisms, you can effectively apply them in various scenarios to improve force, distance, or speed efficiency. Each mechanism has its unique advantages, trade-offs, and considerations, so it's essential to carefully assess your specific application requirements before making a selection.

Section 5: Real-World Applications of Mechanical Advantage Mechanisms

Mechanical advantage mechanisms have found extensive applications across various industries and fields. In this section, we will explore real-world examples that highlight the practical significance and impact of these mechanisms. Let's delve into some notable applications:

5.1 Industrial and Manufacturing Sector: The industrial and manufacturing sector heavily relies on mechanical advantage mechanisms to improve efficiency, productivity, and safety. Some key applications include:

- Conveyor Systems: Pulley systems and belts are widely used in conveyor systems to transport heavy loads across distances. By utilizing mechanical advantage, these systems reduce the amount of force required for movement, allowing for efficient material handling.

- Lifting and Material Handling Equipment: Cranes, hoists, and forklifts incorporate mechanical advantage mechanisms like pulleys, levers, and hydraulic systems to lift and move heavy objects with ease. These systems increase productivity and reduce the physical strain on workers.

- Assembly Line Processes: Mechanical advantage mechanisms are integrated into assembly line processes to streamline production. Robots equipped with levers, pulleys, and screws assist in precise positioning, tightening, and assembly operations, resulting in faster and more accurate production.

- Construction Cranes: Tower cranes utilize pulley systems to lift and position heavy construction materials at great heights. By employing mechanical advantage, these cranes enable the movement of substantial loads with reduced effort and increased safety.

- Earthmoving Equipment: Excavators, bulldozers, and loaders utilize hydraulics and lever systems to manipulate heavy materials and perform tasks like digging, lifting, and pushing. Mechanical advantage mechanisms enhance the equipment's capabilities and optimize performance.

- Scaffolding Systems: Adjustable scaffolding systems incorporate screw mechanisms to raise or lower working platforms. By utilizing mechanical advantage, workers can easily adjust the height of the scaffolding to suit their requirements, ensuring convenience and safety.

- Braking Systems: Automobiles employ leverage mechanisms in brake systems to convert foot pressure into the required braking force. These systems provide efficient stopping power while reducing the effort required by the driver.

- Suspension Systems: Suspension systems utilize various mechanical advantage mechanisms to absorb shocks, enhance stability, and ensure a smooth ride. Lever systems, linkages, and springs work together to optimize vehicle handling and passenger comfort.

- Power Steering: Power steering systems incorporate hydraulic mechanisms to assist the driver in turning the wheels with reduced effort. By utilizing mechanical advantage, power steering systems enhance maneuverability and reduce driver fatigue.

- Skeletal Structure: The human skeletal system acts as a lever system, utilizing mechanical advantage to enable movements such as walking, running, and lifting objects. The arrangement of bones, joints, and muscles optimizes force distribution and movement efficiency.

- Assistive Devices: Prosthetics and orthotics employ mechanical advantage mechanisms to enhance mobility and support individuals with limb deficiencies. These devices utilize levers, pulleys, and other mechanisms to compensate for lost or impaired bodily functions.

- Sports Equipment: Sports equipment, such as golf clubs, tennis rackets, and bicycles, incorporate mechanical advantage mechanisms to optimize performance. Lever systems, gear ratios, and suspension mechanisms are engineered to maximize power, speed, and efficiency.

These real-world examples demonstrate the wide-ranging applications and practical significance of mechanical advantage mechanisms. By harnessing the principles of force, distance, and speed advantage, industries and fields can improve productivity, safety, and overall performance.

Conclusion: Mechanical advantage mechanisms offer invaluable solutions across various industries and fields. From simple tools to complex machinery, these mechanisms enhance force, distance, or speed efficiency, allowing us to overcome physical limitations and achieve remarkable feats.

Throughout this blog post, we have explored the different types of mechanical advantage mechanisms, including levers, pulleys, inclined planes, wedges, and screws. We have also discussed the three types of mechanical advantage systems: force advantage, distance advantage, and speed advantage, highlighting their pros, cons, and trade-offs.

By understanding the principles and applications of these mechanisms, we can make informed decisions when selecting tools, designing systems, or optimizing processes. The practical examples showcased how mechanical advantage mechanisms are utilized in various industries, such as manufacturing, construction, automotive, and biomechanics.

Whether it's lifting heavy loads, improving efficiency in manufacturing, constructing towering structures, or enhancing human mobility, mechanical advantage mechanisms are at the heart of countless innovations and advancements.

So, the next time you encounter a lever, a pulley, or any other mechanical advantage mechanism, take a moment to appreciate the ingenious solutions they offer and the remarkable ways they shape our world.

Remember, understanding mechanical advantage is not just about leveraging physical forces, but also about leveraging our capacity to innovate, create, and overcome challenges. Embrace the power of mechanical advantage, and unlock new possibilities in your endeavors.

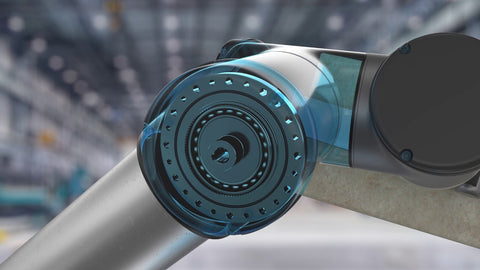

Section 6: Mechanical Advantages in Electric Linear Actuators

Mechanical advantage plays a significant role in the operation of electric linear actuators, enabling them to generate force, speed, and stroke advantages. Let's break down each aspect:

- Force Advantage: Mechanical advantage allows an electric linear actuator to multiply the force applied to the load. This is achieved through the use of mechanisms such as gears or screw threads. These mechanisms create a mechanical advantage by increasing the effective input force applied to the actuator, which in turn generates a higher output force. The force advantage can be calculated as the ratio of the output force to the input force.

For example, in a screw-driven linear actuator, the pitch of the screw determines the force advantage. A finer pitch screw will provide a higher force advantage, allowing the actuator to generate greater pushing or pulling forces on the load.

- Speed Advantage: While mechanical advantage provides force multiplication, it often comes at the expense of reduced speed. However, electric linear actuators can utilize mechanical systems like gears to balance the trade-off between force and speed. By incorporating gear reduction systems, the actuator can increase the speed of the output while decreasing the force applied.

The speed advantage depends on the gear ratios. A higher gear ratio on the actuator's motor side compared to the load side will result in a speed advantage, allowing the actuator to move the load at a higher speed.

- Stroke Advantage: The stroke advantage of an electric linear actuator refers to the extended range of motion it can provide. It is achieved through the actuator's mechanical design, which allows for a longer travel distance compared to the input motion. This can be achieved using mechanisms like lead screws, rack and pinions, or telescopic designs.

In summary, mechanical advantage in electric linear actuators allows for force multiplication, speed adjustment, and extended stroke capabilities. By employing various mechanical systems, such as gears, pulleys, screws, or telescopic designs, these actuators can provide a versatile range of advantages to suit different application requirements.

Section 7: Advancements and Future Trends in Mechanical Advantage Mechanisms

Mechanical advantage mechanisms have a rich history of innovation and evolution, and they continue to advance in the modern era. In this section, we will explore some of the recent advancements and emerging trends in mechanical advantage mechanisms, providing insights into the future of this field.

7.1 Automation and Robotics: One significant trend in mechanical advantage mechanisms is their integration with automation and robotics. With the rapid advancements in technology, robots equipped with sophisticated mechanical advantage systems are being developed for various applications. These robots can perform intricate tasks with high precision, efficiency, and adaptability. The use of advanced materials, sensors, and actuators allows for the creation of robotic systems that can manipulate objects, assemble components, and perform delicate operations with exceptional dexterity and control.

7.2 Miniaturization and Micro-Mechanical Systems: As technology progresses, there is a growing demand for smaller and more compact mechanical advantage mechanisms. Miniaturization and the development of micro-mechanical systems have paved the way for innovative applications in fields such as biomedical engineering, electronics, and micro-robotics. Leveraging the principles of mechanical advantage in miniature devices and systems opens up possibilities for precise manipulation, sensing, and actuation at a micro-scale. These advancements are crucial for applications such as minimally invasive surgeries, micro-electromechanical systems (MEMS), and nanotechnology.

7.3 Smart and Adaptive Systems: The integration of smart and adaptive technologies with mechanical advantage mechanisms is another exciting trend. With the advent of sensors, actuators, and control systems, mechanical advantage mechanisms can now adapt and respond to changing conditions in real-time. This enables the optimization of performance, energy efficiency, and safety. For example, adaptive pulley systems can automatically adjust their configuration based on the load, ensuring optimal force transmission and minimizing wear. Similarly, intelligent lever systems can dynamically modify their mechanical advantage to suit specific tasks or operating conditions, enhancing versatility and effectiveness.

7.4 Additive Manufacturing and Customization: Additive manufacturing, also known as 3D printing, is revolutionizing the design and fabrication of mechanical advantage mechanisms. This technology allows for the creation of complex geometries and customized components, enabling the optimization of mechanical advantage systems for specific applications. 3D printing enables the production of lightweight and intricate mechanisms with precise tolerances, reducing material waste and assembly costs. It also facilitates the integration of multiple functions and features into a single printed component, further enhancing the efficiency and performance of mechanical advantage systems.

7.5 Energy Efficiency and Sustainability: In recent years, there has been a growing emphasis on energy efficiency and sustainability in engineering and design. Mechanical advantage mechanisms play a crucial role in achieving these goals. By reducing the amount of force, distance, or speed required to perform tasks, these mechanisms minimize energy consumption and maximize efficiency. Advancements in materials, lubrication technologies, and control systems contribute to reducing friction, wear, and energy losses within mechanical advantage systems. Furthermore, the integration of renewable energy sources and regenerative braking systems into mechanical advantage mechanisms holds great potential for achieving sustainable and environmentally friendly solutions.

7.6 Human-Machine Interaction and Ergonomics: With the rise of collaborative robotics and human-machine interaction, there is a growing focus on designing mechanical advantage mechanisms that prioritize human ergonomics and safety. Mechanisms that assist and augment human capabilities, such as exoskeletons and wearable devices, are being developed with ergonomic considerations in mind. These systems utilize mechanical advantage mechanisms to reduce physical strain, enhance strength, and improve overall comfort for users. Additionally, haptic feedback systems integrated into mechanical advantage mechanisms provide users with tactile cues, enhancing control and safety in various applications.

As we move forward, these advancements and emerging trends in mechanical advantage mechanisms will continue to shape industries, transform processes, and enable groundbreaking innovations. The combination of smart technologies, advanced materials, and design optimization will further enhance the capabilities and versatility of mechanical advantage systems.

Section 8: Applications of Mechanical Advantage Mechanisms

Mechanical advantage mechanisms find widespread applications across various industries and sectors. In this section, we will explore some of the key areas where these mechanisms play a crucial role, highlighting their significance and impact.

8.1 Industrial Machinery and Manufacturing: Mechanical advantage mechanisms are extensively used in industrial machinery and manufacturing processes. They enable the lifting, moving, and positioning of heavy loads with ease and efficiency. Cranes, hoists, and conveyors employ pulley systems to multiply force and simplify material handling operations. Lever systems are utilized in presses, stamping machines, and mechanical presses to generate high forces for shaping and forming metal components. The precise control and power amplification provided by mechanical advantage mechanisms enhance productivity and safety in manufacturing environments.

8.2 Construction and Engineering: In the construction and engineering sectors, mechanical advantage mechanisms are essential for various tasks. They facilitate the operation of heavy machinery such as excavators, bulldozers, and forklifts, enabling efficient material handling and excavation. Lever systems are utilized in construction equipment for digging, lifting, and moving heavy objects. Pulley systems are employed in cranes and lifting devices to hoist construction materials to great heights. These mechanisms not only enhance productivity but also ensure the safety and stability of construction operations.

8.3 Transportation and Automotive: Mechanical advantage mechanisms have significant applications in transportation and automotive systems. In vehicles, lever systems are used in braking and acceleration mechanisms, providing the driver with control and precise force application. Pulley systems are employed in engines and transmissions to transfer power and multiply torque. These mechanisms contribute to the efficient operation of vehicles, ensuring smooth acceleration, braking, and gear shifting. Moreover, mechanical advantage mechanisms are crucial in suspension systems, allowing for controlled movement and enhanced ride comfort.

8.4 Aerospace and Aviation: The aerospace and aviation industries heavily rely on mechanical advantage mechanisms for a range of applications. In aircraft, lever systems are utilized in control surfaces such as flaps, ailerons, and elevators, enabling pilots to maneuver the aircraft with precision. Pulley systems are employed in landing gear mechanisms, allowing for smooth and controlled deployment and retraction. Mechanical advantage mechanisms also play a role in actuating components like cargo doors, wing flaps, and thrust reversers. These mechanisms are crucial for the safe and efficient operation of aircraft systems.

7.5 Healthcare and Biomedical Engineering: Mechanical advantage mechanisms find important applications in the healthcare and biomedical engineering fields. Prosthetic devices and orthopedic implants often incorporate lever systems to provide mobility and restore function to individuals with limb impairments. Pulley systems are utilized in rehabilitation equipment to assist with exercises and therapy. In surgical procedures, mechanical advantage mechanisms enable precise and controlled movement of surgical instruments, enhancing the dexterity and accuracy of surgeons. These mechanisms contribute to improving the quality of life for patients and advancing medical treatments.

8.6 Sports and Recreation: Mechanical advantage mechanisms are not limited to industrial and professional applications; they also have a presence in sports and recreational activities. Various sporting equipment, such as bicycles, exercise machines, and rowing devices, incorporate mechanical advantage mechanisms to enhance performance and efficiency. Lever systems are used in sporting equipment to amplify force and optimize movement. Pulley systems are employed in gym machines and weightlifting equipment to provide variable resistance and assist with exercises. These mechanisms allow athletes and fitness enthusiasts to achieve their goals more effectively.

8.7 Robotics and Automation: With the rapid advancement of robotics and automation, mechanical advantage mechanisms are becoming integral components of robotic systems. Robots employ lever and pulley systems to replicate human-like movement, allowing them to perform intricate tasks with precision and efficiency. Mechanical advantage mechanisms enable robots to lift heavy objects, manipulate tools, and navigate complex environments. These mechanisms enhance the capabilities of robots in industries such as manufacturing, logistics, healthcare, and exploration. They contribute to increased productivity, improved safety, and expanded possibilities in the field of robotics.

Section 9: Conclusion

In this comprehensive exploration of mechanical advantage mechanisms, we have delved into the various types of mechanisms, including levers, pulleys, gears, and wedges. We have also examined the three types of mechanical advantage systems: force, distance, and speed, understanding their principles and applications.

Mechanical advantage mechanisms offer invaluable advantages in a wide range of industries and everyday life. They provide us with the ability to multiply force, increase distance, and enhance speed, allowing us to overcome physical limitations and achieve remarkable feats. Whether it's lifting heavy objects, moving loads, or transmitting power, these mechanisms simplify tasks, improve efficiency, and enhance safety.

When considering the pros and cons of mechanical advantage systems, it becomes evident that each system has its own trade-offs and considerations. Force-based systems excel at generating high forces but may sacrifice distance or speed. Distance-based systems offer increased range of motion but may require additional force. Speed-based systems enable rapid movement but may sacrifice force or distance. It is crucial to carefully evaluate the requirements of a specific application and choose the appropriate mechanical advantage system accordingly.

As technology continues to advance, we can expect further innovations in mechanical advantage mechanisms. From the development of new materials and designs to the integration of intelligent control systems, the future holds exciting possibilities. These advancements will lead to even more efficient and versatile mechanical advantage mechanisms that can revolutionize industries, improve everyday life, and push the boundaries of human potential.

In conclusion, mechanical advantage mechanisms are the driving force behind many of the technological marvels we encounter in our modern world. They allow us to accomplish tasks that were once thought impossible and make complex processes more manageable.

By understanding the principles and applications of mechanical advantage, we can harness their power to create innovative solutions, enhance productivity, and improve the quality of our lives.

So, whether you're marveling at the massive cranes on a construction site, appreciating the efficiency of a bicycle's gear system, or witnessing the precise movements of a surgical robot, remember that it is the ingenuity of mechanical advantage mechanisms that makes it all possible. Embrace the power of mechanical advantage and unlock a world of endless possibilities.

References:

- Smith, A. L., & Bhatt, N. (2013). Mechanical Advantage and Simple Machines. In Fundamentals of Engineering Design (2nd ed., pp. 114-148). Prentice Hall.

- Bove, A. A. (2017). Introduction to Engineering. New Jersey: Pearson Education.