- Force 500–1124 lb's

- Stroke 6–40 Inches

- Force 900–1500 lb's

- Stroke 6–40 Inches

- Force 22–270 lb's

- Stroke 6–28 Inches

- Force 2200 lb's

- Stroke 10–35 Inches

- Force 200 lb's

- Stroke 5–60 Inches

- Stroke 25.6–39 Inches

- Force 80–180 lb's

- Force 110 lb's

- Stroke 1–4 Inches

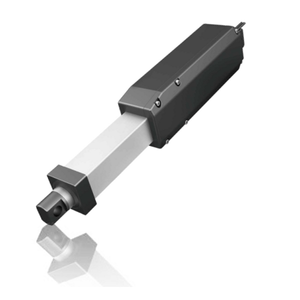

Electric Linear Actuators: The Industry Standard

For over two decades, FIRGELLI Automations has set the benchmark for high-performance Electric Linear Actuators, bridging the gap between consumer accessibility and industrial-grade reliability. Whether you are designing micro-robotics requiring sub-millimeter precision or building heavy-duty industrial lifting systems capable of moving 2,200 lbs, our diverse catalog of UL-certified 12v and 24v DC actuators offers the perfect solution.

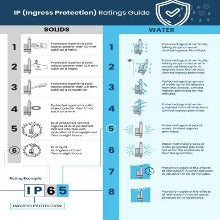

We empower innovation by treating hardware like software. Every Firgelli actuator is backed by a complete "Digital Twin" ecosystem—including downloadable 3D CAD files (STEP), wiring diagrams, and precise force/speed data curves—allowing engineers to simulate motion before fabrication. From IP66 waterproof units for outdoor solar tracking to silent, compact motors for home automation, we stock the industry's widest range of stroke lengths (1" to 60") and force options, shipping same-day from our USA headquarters.

Engineering 101: What is a Linear Actuator?

At its simplest, a linear actuator is a mechanical device that converts energy (usually from a motor) into straight-line motion. Unlike a standard electric motor that spins in a circle (rotary motion), a linear actuator pushes or pulls a load, allowing you to lift, drop, slide, adjust, or tilt objects with absolute precision.

How It Works Internally: Inside a FIRGELLI electric actuator, a 12v or 24v DC motor spins a series of gears. These gears reduce the speed but drastically increase the torque. This torque is transferred to a Lead Screw (or ball screw). As the screw spins, a drive nut—which is locked in place to prevent rotation—rides up and down the threads, extending or retracting the main rod shaft. This simple yet robust mechanism provides high force, static holding power (so the load doesn't drop when power is cut), and reliable repeatability.

Electric vs. Hydraulic vs. Pneumatic

While FIRGELLI specializes in DC Electric Actuators, it is important to understand the other types to make the right choice:

- Electric (Electromechanical): The modern standard for automation. They are clean (no oil leaks), maintenance-free, programmable, and offer precise positional control. They are ideal for home automation, robotics, and automotive tasks where "set it and forget it" reliability is required.

- Hydraulic: Uses pressurized fluid. While capable of immense force, they are messy, require pumps/hoses, are prone to leaks, and require regular maintenance.

- Pneumatic: Uses compressed air. These are fast but "spongy" (springy) and difficult to stop at precise intermediate positions.

Why Electric Wins: For 99% of applications involving smart homes, industrial assembly, or mobile robotics, electric actuators offer the best balance of power, control, and cleanliness. Our units also come equipped with built-in Limit Switches to stop motion automatically at the end of the stroke, and many feature Hall Effect or Potentiometer Feedback sensors, allowing your controller to know the actuator's exact position at all times.

Solving Real-World Problems: Common Applications

Linear actuators are the "hidden muscles" behind thousands of modern conveniences. By choosing the right combination of stroke, force, and speed, you can automate almost anything. Here are the three primary sectors where FIRGELLI actuators dominate:

1. Home Automation & Smart Furniture

In the modern smart home, actuators are used to maximize space and hide clutter. The most popular application is the hidden TV Lift, where a mechanism raises a television from a cabinet or drops it from a ceiling, keeping the screen concealed when not in use. Beyond TVs, our 12v actuators are standard for:

- Kitchen Appliance Lifts: Lifting heavy mixers or espresso machines out of lower cabinets to countertop height.

- Secret Doors & Bookcases: Automating hidden rooms by pushing open heavy shelving units with silent precision.

- Adjustable Desks: Converting standard desks into sit-stand workstations using our Telescopic Column Lifts.

2. Industrial, Automotive & Agriculture

When moving heavy loads outdoors, durability is key. Industrial applications require high-force actuators (up to 2,200 lbs) with high IP Ratings (IP66 or IP67) to withstand dust, water, and harsh weather. FIRGELLI provides the rugged motion control needed for:

- Solar Power: Solar Trackers use actuators to tilt panels to follow the sun, increasing energy efficiency by up to 30%.

- Automotive: Heavy-duty lifts for truck Tonneau covers, engine hoods, and handicap-accessible ramps.

- Marine Automation: Opening heavy fiberglass engine hatches on boats and yachts where corrosion resistance is essential.

- Agriculture: Automating chute deflectors on tractors, chicken coop doors, and fertilizer spreaders.

3. Robotics & Precision Engineering

For robotics, sheer force is less important than precision and size. Engineers use our Micro and Bullet Series actuators where space is at a premium. Crucially, these applications often require Positional Feedback (using internal Hall Effect sensors or Potentiometers) to tell the computer exactly where the actuator is positioned. Common uses include:

- Robotic Arms & Grippers: Providing linear clamping force for end-effectors.

- Medical Devices: Precision adjustment for dental chairs, MRI beds, and prosthetic limb testing.

- Animatronics: Creating lifelike motion for movie props and theme park attractions using compact, high-speed actuators.

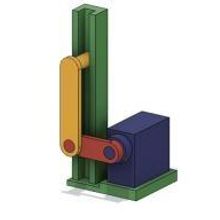

Figure 1: Internal mechanism of a Firgelli Actuator powering Farm, Home, and Industrial applications.

Why Choose FIRGELLI?

We don't just sell parts; we provide solutions. Here is why engineers switch to Firgelli:

- The "Digital Twin" Advantage: We provide 3D files (STEP/CAD) and performance data for every actuator.

- Interchangeability: Our actuators are designed to be drop-in replacements for many other Actuator Automation models.

- In-Stock Guarantee: We ship same-day from Washington State for orders placed before 12 PM PST.

- Comprehensive Warranty: All products come with a 12-month warranty, with options to upgrade to a "No-Questions-Asked" replacement plan.

Technical Resources & Tutorials

The Engineering Guide

Our most comprehensive resource. Learn the physics of motion, how to calculate torque curves, and the 7 critical selection criteria for industrial applications.

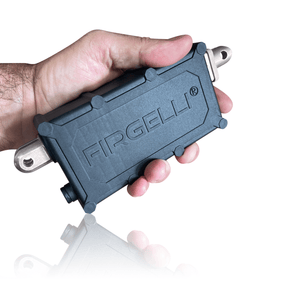

Read the Engineering Guide »Advanced Control & Wiring

Moving two actuators at once? Learn about Synchronized Motion and how to wire our FCB-1 Controller for precise feedback control.

See Synchronization Guide »Frequently Asked Questions

How does a linear actuator work?

Linear actuators convert rotary motion (from a DC motor) into linear motion using a lead screw and gearbox assembly. The motor spins a gear, which turns the lead screw. A nut on the screw is fixed to the extension rod; as the screw turns, the nut travels up or down, extending or retracting the rod. Limit switches at both ends cut power automatically to prevent damage.

How do I choose the right actuator (Force & Speed)?

Force and Speed trade-off against each other. High force = lower speed.

1. Determine Force: Estimate the weight you are lifting. Add a 50% safety margin.

2. Determine Stroke: How far does it need to travel?

3. Select Voltage: 12v is standard for automotive/home; 24v is efficient for industrial use.

Use our Calculator to find the perfect match.

Can I control the speed?

Yes. You can use a PWM (Pulse Width Modulation) Speed Controller to reduce speed, or an Actuator controller that allows up to 4 Actuators to be connected and controlled with the Built-In Timers or Remotes or switches.

Can a FIRGELLI actuator replace my old unit?

Yes. Check the Retracted Length, Stroke Length, and Pin Hole Size. If these match, our actuator will likely fit. We offer brackets to adapt to almost any mounting requirement.

Do you offer volume discounts?

Yes. Discounts start at quantities of 11+ units. Contact our sales team for OEM and bulk pricing.

What can I build with a linear actuator? (Project Ideas)

Actuators are used to automate thousands of DIY and industrial projects. The most common applications include:

- Home Automation: Hidden TV Lifts, spice racks, and appliance garages.

- Outdoor & Farm: Solar Panel Trackers and Automatic Chicken Coop Doors.

- Marine & Automotive: Motorized Boat Hatches, Truck Tonneau Covers, and Engine Hood Lifts.

- Robotics: Robotic Arms and Halloween Animatronics.

Want to see how to build these? Check out our Guide to 15 Common Actuator Projects for step-by-step instructions.

How to request or submit warranty claim

To submit a warranty claim, please email support@firgelliauto.com with the following information:

- Your Firgelli order number

- Application details, including duty cycle and operating environment

- A clear description of the issue, including:

- Observed behavior of the actuator

- Whether the actuator is making unusual noise

- Any changes in performance

Providing complete details will help us assess your claim as quickly as possible.

General Warranty Terms and Conditions

The warranty is valid only if the equipment has been used within the applicable operating specifications.

- The equipment must not have been exposed to abusive treatment, excessive shock or vibration, fluids other than fresh water, water in excess of given specified IP ratings, dust or particulates in excess of specific IP rating, or hazardous conditions.

- Firgelli Automations shall not be liable for the cost of removal, installation, for loss or damage to, or loss of use of facilities, loss of revenue or other damages or costs of any kind whether direct, indirect, incidental or consequential arising from the failure of Firgelli Automations products.

- This warranty shall be voided as to any products which have been repaired, worked upon, or altered by persons not authorized by Firgelli Automations, or which have been subject to misuse, negligence, accident, or overload. In no event shall Firgelli Automations be liable for any incidental or consequential damages.

- Periodically inspect mounting points, wires, electrical connections, observe unit in operation for any irregularities or changes in behavior.

Top Blog Posts for Linear Actuators

This article will give you a basic understanding of how actuators work and the terminology used to describe them. When you understand the basics it...

IP Ratings are given to any product that requires electricity or has moving parts or both. The IP rating contains a range of information within...

The most common method to mount your linear actuator is to use what is called clevis end mounting brackets. These common mounting methods consist of mounting the brackets at each end of the linear actuator...

Arduinos are an open source electronics prototyping platform based on flexible, easy-to-use hardware and software. It's intended for DIY projects, artists, designers, hobbyists, and anyone interested in creating interactive projects. Arduinos are microcontroller boards that contain everything you need to easily interface with the microcontroller.

Arduinos are an open source electronics prototyping platform based on flexible, easy-to-use hardware and software. It's intended for DIY projects, artists, designers,...

From automotive to machinery to home improvement, actuators are becoming more commonplace worldwide. This is most true in developing countries going through their industrial revolution....