FIRGELLI® Micro Linear Actuators

Micro Linear Actuators are used in applications where either space is limited or the stroke requirements are limited. If you need to move something small or not very far, then a Micro Linear Actuator would be ideal for your application. If you are looking for an actuator with more power and stroke, check out our Standard Linear Actuators. Not sure what type of actuator you need? Our Actuator Calculator will help you chose which actuator is best for your specific project.

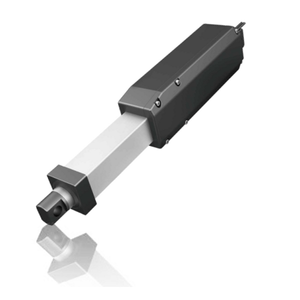

Micro Linear Actuators: The Artificial Muscles for Humanoid Robotics, FIRGELLI's Micro Pen Actuator

In the race to build functional, scalable humanoid robots, the challenge isn't just AI—it's Physical Intelligence. How do you fit 27 degrees of freedom into a human-sized envelope? How do you engineer a hand that grips an egg delicately but lifts a power tool securely?

The answer lies in moving beyond bulky rotary servos and embracing direct, bio-mimetic linear motion. FIRGELLI Micro Linear Actuators are designed to solve the "packing problem" in advanced robotics. With diameters as small as 16mm (0.63”), our actuators function as synthetic tendons, allowing you to stack motion systems inside finger phalanges, forearms, and tight chassis envelopes where traditional motors simply won’t fit.

Why Robotics Engineers Choose Firgelli Micro Actuators:

-

The "Finger-Size" Form Factor: Our Micro Pen Actuator features a streamlined aluminum T6063 body that mimics the metacarpal structure. You can mount them side-by-side to drive individual fingers or complex end-effectors without creating a bulky "Popeye forearm" effect.

-

Closed-Loop Precision: Autonomous operation requires knowing exactly where your joint is. Our actuators feature built-in Dual Hall Effect Sensors (90° phase shift), delivering up to 45 pulses per mm (1143 pulses/inch) of positional resolution. This enables the fine control necessary for soft-touch gripping and precise gesture repeatability (0.1mm).

-

Force Density, Not Hype: We offer three distinct gearing options to match your specific joint requirements:

-

High Speed (20N / 4.5lbs): For rapid finger flexion and blinking mechanisms.

-

Balanced (50N / 11lbs): For wrist articulation and utility motion.

-

High Force (100N / 22lbs): For locking mechanisms and heavy grip applications.

-

-

Standardized Reliability: With IP66 protection, overload clutches, and standard 12V inputs, FIRGELLI actuators provide the "picks-and-shovels" infrastructure you can trust, allowing your team to stop reinventing the wheel and focus on the intelligence code.

From facial animatronics with 20mm strokes to tendon-driven forearm systems with 100mm strokes, FIRGELLI provides the linear motion solutions that turn digital commands into physical reality.

Build your robot with the industry standard.

The Engineering Advantage: Micro Footprint, Macro Impact

While standard linear actuators drive the heavy lifting of industrial automation, Micro Linear Actuators solve the critical "packaging problem" inherent in humanoid and service robotics. When you are designing a robotic hand, a facial animatronic system, or a compact locking mechanism, a standard actuator simply won't fit the envelope.

Firgelli Micro Actuators condense the same robust lead-screw technology found in our industrial lines into a compact form factor that fits where others fail. Despite their miniature profile, they do not compromise on utility; our Micro Utility line delivers forces up to 38 lbs (170N), bridging the gap between weak hobby servos and bulky industrial hardware.

Why Engineers Specify Firgelli Micro:

-

Bio-Mimetic Integration: Their slender profile allows for "muscle-like" placement inside limb structures and chassis voids.

-

Rapid Prototyping to Production: Designed for easy mounting and setup, our actuators are supported by extensive 3D models and technical documentation, accelerating your development cycle from concept to functional prototype.

-

Scalable Economics: Firgelli’s continuous R&D and global supply chain focus on reducing cost without sacrificing precision. We provide the reliable, cost-effective infrastructure that makes mass-producing viable service robots a reality.

Applications & Engineering Use Cases

While Firgelli Micro Actuators are versatile enough for hobbyist projects, they are engineered for critical applications where precision cannot be compromised by space constraints.

-

Robotics & Bionics: This is the frontier of "Physical Intelligence." Our actuators are the industry standard for driving end-effectors and grippers, providing the grip force necessary for robotic hands. They are also integral to advanced prosthetics, serving as the silent, compact muscles that articulate bionic limbs and fingers with life-like fluidity.

-

Automotive & Autonomous Systems: Modern vehicle architecture demands hidden motion. Engineers utilize our micro actuators for deploying LIDAR/sensor arrays in self-driving stacks, active aerodynamic flaps, and automating interior latches and mirrors.

-

Medical & Laboratory Automation: In environments where hygiene and precision are paramount, our actuators drive fluid pumps, adjust surgical assist tables, and automate analysis equipment. Their high repeatability ensures consistent performance in lab automation tasks.

-

Precision Agriculture: Efficiency in farming relies on accuracy. Our actuators are deployed in smart agricultural machinery to fine-tune the height and angle of sprayers and control seed planting depth. This granular control helps automate complex harvesting and planting tasks that previously required manual adjustment.

The Agricultural Industry is also taking advantage of micro linear actuators to help improve efficiency and reduce its costs. Thanks to linear actuators, agricultural machinery has never been more reliable. for example, the height and angle of sprayers can be controlled to provide consistency when used on crops. There are many other tasks that require pinpoint accuracy being done by micro linear actuators such as planting seeds to increase efficient use of land, being used in combine harvesters, and so on.

Resources and Help

We have split up our resource pages into two sections. Firstly our "Linear Actuators 101" to more detailed and advanced engineering articles such as "How to achieve Synchronized motion".

Our other big resource section is our Tutorials page. Here we get much more specific with some actuator controlling features for more advanced users and applications. If we don't cover anything that suits your needs then you can always call our tech team at 1-866-226-0465 or email us at support@firgelliauto.com and please feel free to send us drawings, sketches, napkin notes, or whatever you have that may help us help you.

.

Frequently Asked Questions

A Micro Linear Actuator, which is a small actuator, is a device that requires an energy source input and an external signal input. These inputs create an output usually in the form of motion that can be either rotary or linear. An Electric Linear Actuator is a device that converts the rotational motion of an AC or DC motor into linear motion. It can provide both push and pull movements. This movement makes it possible to lift, drop, slide, adjust, tilt, push, or pull objects with the simple push of a button. Today there are hundreds of millions of Actuators used in the world to perform many different tasks. An Electric Micro Linear Actuator consists of a DC or AC motor, a series of gears, and a lead screw with a driving nut that pushes the main rod shaft in and out. FIRGELLI sells 12v Linear Actuators and 24v Linear Actuators.

There are many factors which you need to take into account when choosing which micro linear actuator you need for your project. Mainly the Stroke and Force. If you know the stroke and force that you need, then you can use our Actuator Calculator to work out which micro actuator is best. Other factors could include how much space you have available for the retracted actuator to take up, as well as the speed of the micro actuator. Compare our micro actuator's dimensions to what you need to see which fits the best. If you are unsure our team at Firgelli is happy to help, give us a call.

Now that you have decided which micro actuator you will use, you will need to consider how you will control your actuator. At Firgelli we have many different Switches, Remotes, and Arduino which can all be used depending on your preference. Head over to our Actuator Controls page to find the right control option for you.

The first thing to know is that a micro linear actuator does exactly what its name implies: it actuates (or 'moves') in a linear (or 'straight') fashion. There are many different ways that a motor can do this, and their motion is commonly achieved with a rod extending and retracting, or a slider that moves on a track. The linear motion is created by using a Lead-screw. The screw turns either clockwise or counter-clockwise and this causes the shaft, which is basically a nut on the screw to move up and down the screw as the screw turns. This is what converts rotary motion from the electric motor to Linear motion.

The motors used are either AC or DC motors, most however run on 12v dc. To make a Linear Actuator go the opposite direction you simple reverse the wires from the Actuator (reverse polarity) from the battery or power supply. This is typically done through a switch that automatically reverses the polarity to the motor for you. Different speeds and forces are achieved by using different gear ratio's inside the Linear Actuator gearbox system. Please remember in our micro actuators, or rather all Linear Actuators, force and speed trade off against each other. That means if you want high force you have to settle for a lower speed than if you require lower force. This is because the only constant in a Linear Actuator is the Motor speed and force for a given input voltage.

To make the shaft stop when it gets to the end of the stroke, our products have built-in limit switches or micro switches as they are sometimes known. These limit switches are inside the main shaft and are nothing more than a small switch that is triggered by the nut inside that slides up and down the screw. There is one for the top extended position and one for the lower retracted position. For more information on this, check out our Blogs page.

Yes, you can save on your order when purchasing our Actuators in large volumes. Discounts will be calculated at checkout. Our base discount is 20% when you purchase a minimum quantity of 11 units of an actuator, and then the discount scales up as you purchase more. The full discount information table can be found on each actuator product page.

Top Related Blogs for Micro Actuators

In Simple terms, Micro Linear Actuators are basically a Small Actuator with a small body size and therefore a small stroke range. A typical Micro Linear...

Used in thousands of applications across numerous industries, this little tool has more of an impact on our daily lives than you might think. But what are micro...

Arduino are an open source electronics control system that's ideal for Micro Actuators of all kinds, their based on a flexible hardware and software system that's easy to learn and use. It's not only intended for DIY projects, artists, designers, hobbyists, but anyone that needs a custom control system for Linear Actuators and motors. Arduinos are microcontroller boards that contain everything you need to easily interface with the microcontroller.

Arduino are an open source electronics control system that's ideal for Micro Actuators of all kinds, their based on a flexible hardware...