- Recommended TV Size: 0" - 50"

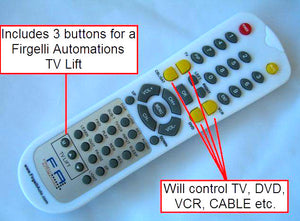

Actuator Switches

Manual switches are the most fundamental and reliable method for controlling linear actuators. Firgelli provides high-durability DPDT (Double Pole Double Throw) rocker and toggle switches specifically designed to handle the inductive loads of DC motors. By physically reversing the polarity of the power circuit, these switches allow for instant extension and retraction control. They are the ideal solution for applications where human-in-the-loop operation is required, such as adjusting workspace ergonomics, opening access hatches, or deploying marine equipment.

We offer a comprehensive selection of control switches to suit any project requirement. Choose from Momentary switches, which provide precise, inch-by-inch movement only while the button is pressed, or Sustaining (Latching) switches that allow the actuator to travel its full stroke with a single press. For complex installations, utilize our wiring diagram generator to visualize exactly how to connect your switch, power source, and actuator for safe, reliable operation.

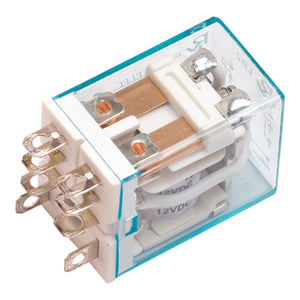

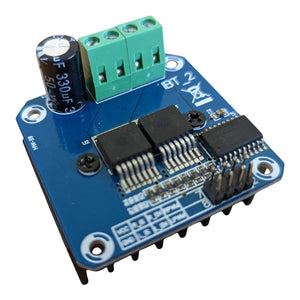

Actuator Relays

Relays are the critical bridge between low-voltage control logic and high-power motion. They allow you to control heavy-duty linear actuators using low-current triggers from sensors, remote controls, or microcontrollers. By isolating the high-amperage motor circuit from your delicate control electronics, relays prevent voltage spikes and switch burnout, ensuring the longevity of your automation system.

Our inventory includes both SPDT (Single Pole Double Throw) and DPDT (Double Pole Double Throw) relays, essential for creating H-Bridge circuits that reverse motor direction. Whether you are building a hidden trapdoor triggered by a 12V signal or automating a solar tracker, relays provide the switching capacity needed to drive high-force actuators safely. They are the industry standard for integrating linear motion into smart home systems and industrial PLCs.

Note: Relays manage the switching logic, but they do not supply power. A robust power supply capable of handling the actuator's startup surge current is mandatory to prevent relay chatter and ensure smooth motion.

Power Supplies

A linear actuator is only as strong as the power source driving it. Firgelli offers high-efficiency AC-to-DC power supplies designed to meet the rigorous demands of DC motors. Whether you require a standard 12VDC supply for residential projects or a 24VDC system for industrial machinery, our power units provide clean, consistent voltage to ensure maximum force output and speed stability.

Choosing the right power supply is a matter of physics: Force equals Amps. As the load on an actuator increases, its current draw rises. Using an under-rated power supply will result in stalled motors, slow operation, or overheating components. For example, a heavy-duty actuator lifting 2,000 lbs may draw over 10 Amps; your power supply must be rated to handle this peak load continuously. Our range ensures you have the amperage overhead required for reliable, full-force operation.

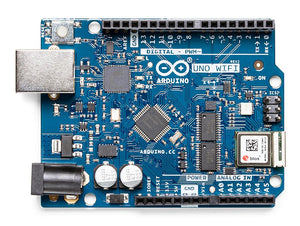

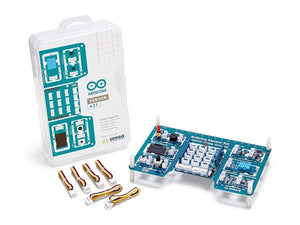

Micro-Controllers and Arduino

For applications demanding precision and intelligence, simple switches are often not enough. Firgelli’s Synchronized Control Boards provide plug-and-play management for multiple actuators. By reading feedback from built-in Hall Effect or Optical sensors, these controllers ensure that 2 to 4 actuators move in perfect unison, preventing mechanical binding on uneven loads—an essential feature for lifting large platforms, desk surfaces, or heavy lids.

For custom robotics and automation, Arduino microcontrollers offer limitless potential. By writing custom code, you can program actuators to react to environmental sensors (temperature, light, proximity) or execute complex motion sequences. While this requires programming knowledge, integrating an Arduino allows for features like soft-start, precise positional memory, and integration with IoT (Internet of Things) networks, turning a simple mechanical movement into a smart device.

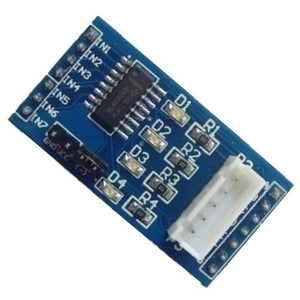

Timer Relay

The Timer Relay is the ultimate solution for "set-it-and-forget-it" automation. It allows you to program linear actuators to cycle automatically based on time intervals, without the need for complex computer coding. Ideally suited for applications like automatic animal feeders, solar panel adjustments, or scheduled ventilation hatches, the timer relay can be configured to delay, cycle, or trigger motion at precise moments. This component adds a layer of time-based logic to your system, transforming a manual mechanism into a fully autonomous robot.

Frequently Asked Questions

If you need to run 2-4 linear actuators in perfect synchronization, then you will need a control board. For this feature to work you will need to be using linear actuators that have feedback. Apart from the ability to synch linear actuators movement, our control board offers a range of beneficial features for your application, including adjusting actuator speed, customizing start and stop positions, and implementing timer controls for scheduled activation. For further details, explore our synchronous control board.

To control a linear actuator with an Arduino, you'll first need an intermediate component to interface between the actuator and the Arduino. The most commonly used component for this purpose is a relay. Connect the Arduino to two single-pole double-throw relays, which are used to control the polarity of the voltage applied to the linear actuator, enabling its extension and retraction.

In our setup example, we also attach two buttons to the Arduino to facilitate the control of the actuator's movement. You'll need to write code to assign each button press to activate the corresponding relay coil, which, when energized, causes movement in the linear actuator.

For a visual explanation of our setup and more detailed information, watch our video tutorial. Additionally, we have a blog post dedicated to this subject for further reference.

Actuator switches are components designed to facilitate the control of linear actuators. They provide a method to manage the extension and retraction of actuators, offering precise movement.

Typically, actuator switches consist of buttons or switches that, when pressed or toggled, send signals to the actuator's control system. This system then interprets these signals to initiate the desired action, such as extending or retracting the actuator.

For example, pressing the "up" button on an actuator switch signals the actuator's control system to extend the actuator to the desired position. Pressing the "down" button initiates the retraction process, returning the actuator to its original position.

The direction of movement can be easily customized based on how the actuator switch is wired, allowing for versatile applications across various industries and projects.

For a visual explanation of our setup and more detailed information, watch our video tutorial. Additionally, we have a blog post dedicated to this subject for further reference.

Actuator relays are components used to control linear actuators by receiving a signal, typically a pulse signal, from another device. These relays are crucial for precise and efficient control over actuator systems. They operate with a 12V DC signal, which triggers the relay to activate and initiate movement in the actuator.

Relays come in various configurations, including Double Pole Double Throw (DPDT), Single Pole Single Throw (SPST), and Single Pole Double Throw (SPDT). Each type offers different levels of control, allowing users to achieve precise movement tailored to their application requirements.

In operation, when the relay receives a signal, it switches the flow of current, effectively controlling the actuator's extension or retraction. This enables users to exert control over the actuator's movement based on their specific needs.

We go more into detail in our blog post on the subject. Additionally a video on linear actuator relays is below.

Top Blog Posts for Linear Actuator Controls

![FCB Set-Up & Video Guides [Update: 2025]](http://www.firgelliauto.com/cdn/shop/articles/IMG_0833_520x500_520x500_2c840c2c-9fd5-42ec-b785-ca5d770996d4_300x300.jpg?v=1767812441)

Achieve synchronized motion with Firgelli's Control Boxes! These new controllers maintain precise movement within 1/8" for up to 4 actuators, set limits and speeds, and...