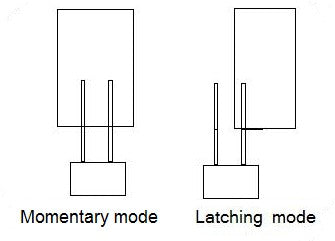

To change from momentary to latching mode

The remote system comes programmed in momentary mode; this means that the actuator will move for as long as your finger is held on the button. In latching mode you only have to press the button once and the actuator will go all the way to the end until it reaches its internal limit switch then stop.

To change this all you have to do is look at the front of the case and you will see a black jumper block, remove the jumper that connects 2 pins together and place it on just 1 pin, then you need to remove the power to the remote receiver and then apply the power again, this resets the system, See below.

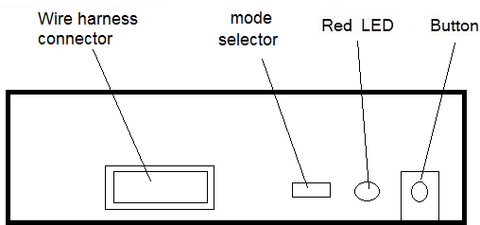

Programming more remotes

To program more remotes you press and hold the button on the circuit board, you will have to open the case first. Hold the button for a few seconds until the red LED flashes. Then press any button on each of the remotes you want to program, 1 at a time, so if you have 4 remotes you need to program all the remotes, even if they were already programmed, and just press any one of the buttons on each remote. Then remove the power from the receiver and plug it back in again. Now all remotes should work with the receiver

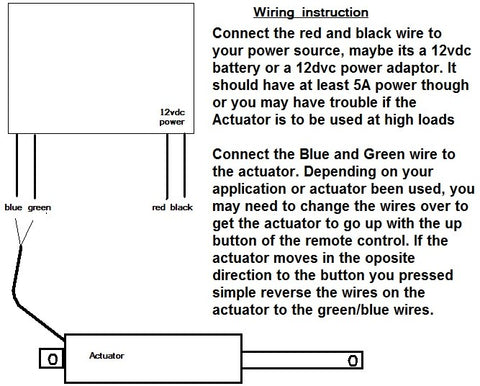

Exceeding a load of 5 amps

The remote control board is rated for a maximum current draw of 5 amps, which makes it compatible with most of our standard linear actuators including the Premium and Classic series. However, some of our high force actuators such as the Industrial Heavy Duty Actuator are rated for a current draw of 20 amps. Connecting such an actuator to this control board will irreversibly damage the board.

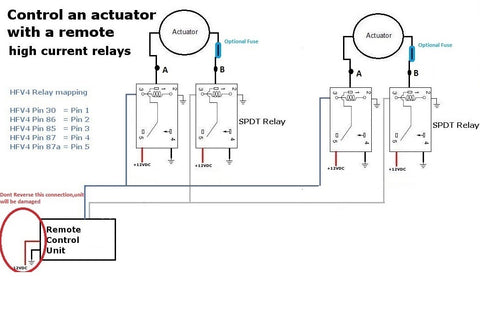

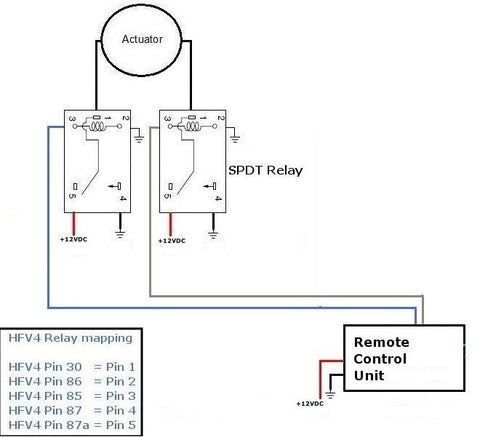

Instead we advise using a pair of SPDT 20 amp relays (and optionally a wiring harness) to isolate the remote control board from the actuator. Wire the circuit as shown in the picture below.

Connecting multiple linear actuators

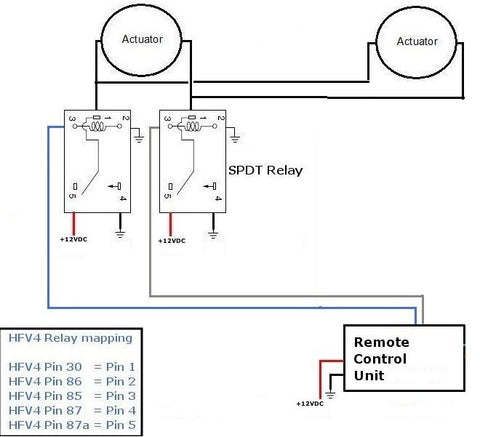

For the reasons of increased current draw, discussed above, never connect more than one actuator directly to the control board. These boards are only rated for a current of 5 amps, connecting two or more actuators can permanently damage the control board. Instead use a pair of relays to isolate the control board from the actuators. See wiring diagram below. Note that the power supply must be rated for a sufficiently high current, depending on the number of actuators.

It should be noted that despite being connected to the same power supply, the actuators will not necessarily move at exactly the same speed although they will be very close. There are a number of contributing factors to this, and this topic is discussed in greater detail in our tutorial on synchronous control of liner actuators:

If instead of moving two actuators together via remote you want to use two actuators, but controlled separately, please refer to our tutorial on the 4 channel remote control system.

Connecting multiple linear actuators that exceed the relay's rated current

Because each SPDT relay we sell is rated for 20 amps, the above circuit works we for most of our 12V 5A linear actuators (in fact you can connect up to four actuators using the above circuit). If however you are using 2 of our Heavy Duty Industrial Actuators, which are each rated for 20 amps, these relays are not suitable (2 actuators at 20 amps means a total of 40 amps through each relay, exceeding its rated limit). Instead connect them as shown in the following diagram. Note that you will need an appropriately sized power supply (either one 12V 40 amp supply or two 12V 20 amp supplies, one connected to each relay pair).