Replace an Actuator using these simple steps

Contents

In this article, we provide quick tips to help you find a suitable replacement actuator, accompanied by a short video and the bottom of this page to use as a visual aid, that explains and demonstrates the process. Its not always easy to find a direct replacement Actuator, this could be due to various reasons: the original actuator might be discontinued, or you might be unable to locate the original product label or the manufacturer's name.

Quick Guide: How to Replace an Actuator step by step

Replacing an actuator when its label is missing can be a daunting task, and in this guide we will operate under the assumption that you cannot replace your current actuator with the exact same model due to reasons we previously mentioned above. Therefore our goal is to help you find a replacement that closely matches your existing actuator. We'll explore various methods to help you find the most suitable unit for your needs.

Step 1: Measure Actuator Stroke

Start by measuring the stroke length of your existing actuator. The stroke length is a primary factor in selecting actuators, as it's the most critical variant. Wondering how to determine the stroke length? Just follow these steps:- Fully retract the actuator (assuming its still working, if not keep reading we will show you another method)

- Measure the length of the shaft sticking out.

- Extend the actuator fully and measure the shaft length again.

- The difference between the two measurements is the stroke length.

If your Actuator is not working then measure the hole to hole dimensions on fhte device the actuator was used in. First in the closed position measure the pin to pin hole center dimensions, then manually if possible open your device to its fully extended position and measure the same two points. The difference is the stroke.

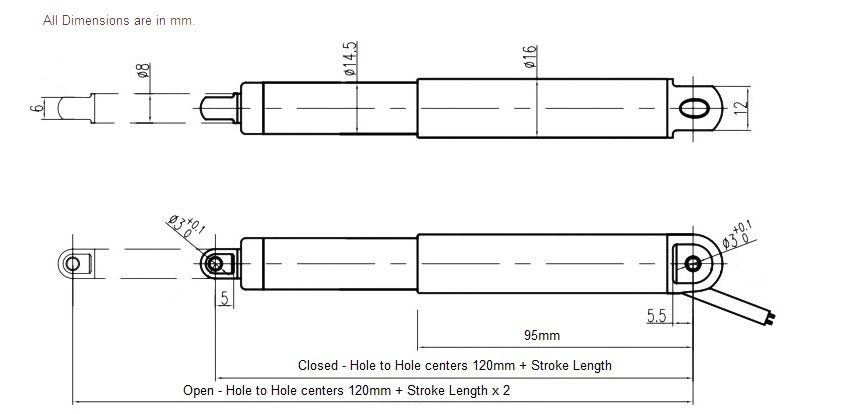

The accompanying images below illustrates a typical actuator measuring the Hole-to-Hole dimensions when open and closed.

Above: Linear Actuator measured when fully open

Above: Linear Actuator measured when fully closed

Step 2: Evaluate Actuator Force Rating

After determining the stroke length, which is crucial, the next step is to understand the force required for pushing or pulling. If possible, observe the actuator's force rating in action:

- Note the speed of the actuator when it's not under any load. A quickly moving actuator typically indicates a high force capacity, while a slower movement suggests lower force. Measuring the speed (usually in inches per second, inch/sec) allows you to compare it with different actuator models, choosing ones with similar characteristics to what you've measured. Remember, these are no-load speeds. The speed will significantly change under full load. If possible, measure the actuator's speed under full load to find a comparable replacement.

- If you already know the exact force your existing actuator can exert, use this figure as a baseline for finding an alternative. However, it's important to add at least 25% more force capacity. Ideally, you don't want to operate your actuators at 100% of their load capacity; aiming for about 60-80% is more desirable.

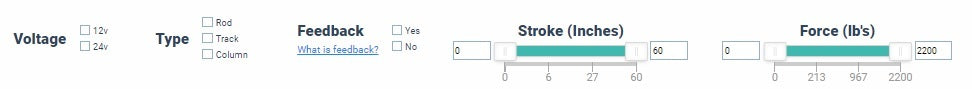

Step 3: Filter for your perfect actuator

Visit this page and use the actuator selector wigit at the top of the screen to provide the tools you need to find a suitable replacement actuator.Step 4: Confirm Installation Distance

Determine the installation distance, also known as the hole-to-hole dimensions. This refers to the space between the mounting points of the actuator. Measure this dimension either directly from the actuator or from the application where it's installed

Step 5: Assess Electric Power Rating

Identify the actuator's power source, typically either alternating current (AC) or direct current (DC). Common AC ratings are 110VAC or 220VAC, while DC options include 12VDC, 24VDC, and 48VDC. This information is usually indicated on the power source itself. All Actuators have some sort of power source and you need to identify this to find a suitable replacement.Step 6: Analyze IP Rating

Check the Ingress Protection (IP) rating, which defines the environmental conditions the actuator can handle effectively. For indoor applications, lower IP ratings (IP20 to IP54) are often sufficient. Outdoor or harsh environments may require higher IP-rated units (IP6 to IP67) capable of withstanding dust and moisture exposure.Step 7: Considering Feedback Sensors.

Check if your old actuator includes feedback sensors, like potentiometers or Hall effect sensors. Inspect the output cord; actuators without feedback sensors typically have only two wires connected to the motor.

Step 8: Find the Replacement Actuator

Use the linear actuator filter widget on the FIRGELLI Automations website to refine your search. Input the stroke length, speed, and other specifications you've collected. This tool will help you narrow down your options efficiently. By following these steps, you can confidently select the ideal replacement actuator, even in cases where your existing actuator is missing labels or identifiable information.

Whilst this is a quick guide to help you quickly find a replacement Actuator, we have also written a more detailed article on his subject. You can view our other article here.