Step-by-step Guide on how to replace an actuator

Replacing an actuator is a crucial task in maintaining various mechanical systems. Wondering how to do it correctly? In this article, we'll guide you through the essential steps, ensuring your equipment operates smoothly. Stick with us to learn the ropes of this fundamental maintenance process.

All actuators, basically have one main differentiating feature, the stroke. The stroke therefore is the best place to start in identifying the right type of actuator – specifically you need to replace. What is the stroke of the unit you are trying to replace, is your first starting point.

The stroke length refers to the distance the actuator can travel, and the force rating indicates the maximum load it can handle, either pushing or pulling force. These specifications are crucial for ensuring the new actuator meets the exact requirements of your application.

Additionally, consider the voltage requirement, which commonly falls within the 12Vdc or 24Vdc range. This information is essential for seamless integration into your existing setup. By adhering to these three critical criteria – type (electric linear), stroke length, force rating, and voltage – you can confidently navigate the selection process and find the perfect replacement that aligns precisely with your needs. Using our Linear Actuator selector tool you should easily be able to find the perfect replacement Actuator. Using our tool you can select the replacement actuator based on either the Force or Stroke.

Evaluating Actuator Force Rating

It's essential to ascertain the force rating of your actuator before seeking a replacement. This rating indicates the force the unit can exert, either pushing or pulling. Typically found on the unit's label, this information is expressed in units like pounds (lbs) or newtons (N). Selecting a replacement actuator with a force rating capable of accommodating your application's load is crucial. Opting for a slightly higher force rating than strictly required provides an added safety margin. So firstly look on the label of the Actuator you are trying to replace to see if there is a Force Rating. If you cannot find a force rating then look for a Model number of the actuator, from here you can google the model number along with typing "Force rating" and Google should give you the results. If the model number is no written anywhere, perhaps because its worn off or removed, then you will somehow need to measure the weight of the object it is lifting or pushing.

Measuring Stroke Length

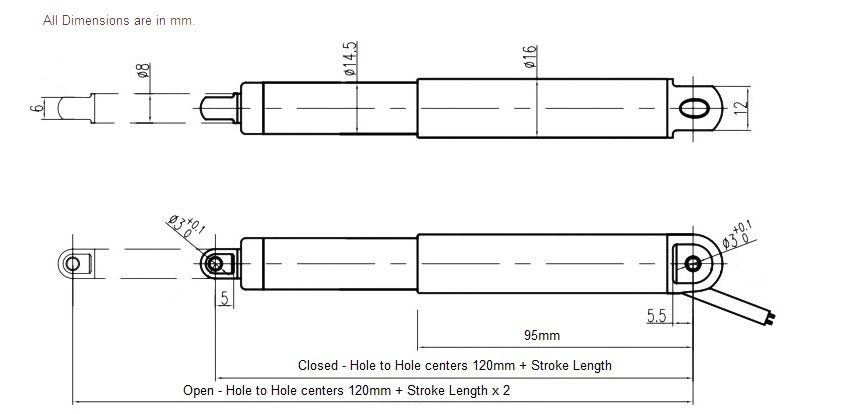

The distance your actuator needs to travel, known as its stroke length, is the next critical consideration. This specification is often provided on the product label, but if absent, it can be measured directly. Measure the fully extended length of your existing linear actuator and subtract the length when fully retracted to determine the stroke length accurately.

Confirming Installation Distance

The installation distance, also referred to as the mounting distance or hole-to-hole distance, denotes the space between the actuator's two mounting points. These points generally include the mounting hole at the rod end and the corresponding hole at the motor end. You can measure this dimension from either the actuator itself or the application in which the actuator is installed. Accurate measurement of this parameter is vital to ensure the replacement actuator fits seamlessly into your setup. This is where you are likely to have trouble finding a direct replacement because most brands have their own design and so have different dimensions. You may need to get creative with adjusting your applications to accommodate a slightly different installation size.

Assessing Electric Power Rating

Understanding the power source driving your actuator is straightforward but pivotal. The power source could be an electrical outlet, a battery, or an adapter. This information is typically indicated on the power source itself. It's essential to distinguish between alternating current (AC) and direct current (DC) power sources. AC power sources might include common ratings like 110VAC or 220VAC, while standard DC power options encompass 12VDC, 24VDC, and 48VDC.

Analyzing IP Rating

The Ingress Protection (IP) rating dictates the environmental conditions under which the unit can operate effectively. If your application is confined or indoors, a lower IP rating (IP20 to IP54) is often sufficient. In contrast, outdoor or harsh environments necessitate higher IP-rated units (IP65 to IP67) capable of withstanding exposure to elements like dust and moisture.

Unit Speed and Noise Level

Although these specifications might not be readily accessible for all units, they're often provided in the unit's datasheets. If these datasheets aren't available, you can measure speed and noise level yourself during operation. If these parameters aren't mission-critical for your application, approximations can suffice.

At FIRGELLI Automations, each actuator listed on our website is accompanied by a datasheet containing comprehensive specifications and dimensional drawings. Utilizing our filter options for force, stroke, speed, feedback, and IP rating simplifies the process of identifying the optimal actuator for your specific application.

Considering Feedback Sensors

Examining whether your old unit features feedback sensors, such as potentiometers or Hall effect sensors, is the final step. A straightforward approach involves inspecting the output cord. Typically, units lacking feedback sensors will possess only two wires stemming from the motor. If additional wires are present, the unit may incorporate internal feedback sensors.

Get in Touch with FIRGELLI Automations

After gathering the necessary information from your existing actuators, feel free to contact FIRGELLI Automations. Our team of experienced product engineers is readily available to guide you through selecting an appropriate actuator replacement. With our expertise, you can confidently transition from a malfunctioning actuator to a high-performing replacement that aligns seamlessly with your application's requirements.