Why choose electric linear actuators for your equipment design? |

| 1. Programmable |

| 2. Accurate |

| 3. Customizable |

| 4. Safe |

| 5. Synchronizable |

| 6. Sustainable |

| 7. Compact |

| 8. Maintenance free |

| 9. Energy efficient |

| 10. Ergonomic |

Explore the advantages of electric linear actuators as a sustainable substitute for pneumatic and hydraulic systems. Unlock numerous benefits for your engineering projects. Find 10 compelling reasons to embrace electric linear actuators in your upcoming equipment development endeavors.

The demand for cutting-edge equipment is continuously rising to fulfill increasingly advanced technological demands. Manufacturers and consumers alike seek the latest innovations that enhance safety, speed, precision, ergonomics, and functionality. These innovations aim to simplify lives and boost productivity and efficiency.

Why choose electric linear actuators for your equipment design?

Electric actuators play a vital role in product development across various industries. From linear actuators to lifting columns and gear motors, they seamlessly integrate into industrial, medical, domestic, and ergonomic applications. These versatile actuators enable smooth movement, allowing for pushing, pulling, raising, lowering, and load orientation. With their growing power and sophistication, electric actuators are gradually replacing cumbersome hydraulic and pneumatic systems. Uncover the multitude of advantages offered by electric linear actuators.

List of the 10 advantages of electric linear actuators

1. Programmable

Electric linear actuators operate in conjunction with an electronic control box, which can be either external or integrated. This control box, equipped with advanced software, effectively manages and coordinates the various movements required by the application. Consequently, a wide range of parameters can be precisely programmed, including speed, stroke, safety functions, and motor synchronization. This level of control allows for fine-tuning and customization to meet specific operational requirements.

2. Accurate

Electric actuators excel in delivering exceptional precision in both movement and control. They ensure smooth, seamless motion characterized by jerk-free operation and a soft start and stop function. Moreover, electric actuators offer precise control that can be tailored to meet specific requirements. For instance, it is possible to program variable speeds within the stroke, accommodating applications that demand such flexibility. This level of customization extends to other parameters as well, ensuring a highly adaptable solution.

3. Customizable

Electric actuators offer extensive customization options to meet precise specifications. Regardless of your application requirements, you can define critical parameters such as speed, stroke, type of attachment, and many others. This level of customization ensures the creation of an electric motion system that precisely aligns with your project's needs. With the ability to tailor the electric actuators to specific requirements, you can achieve optimal performance and functionality for your application.

4. Safe

Electric actuators can incorporate several safety options to ensure longevity and protect both users and equipment from potential damage. These safety features cater to various needs, including:

- The thermistor (PTC): It detects and responds to high temperatures by shutting off the motor, preventing overloads that could harm the actuator.

- Safety nut: Integrated into the actuator, it supports the load in the event of spindle nut breakage or failure.

- "Push only" function: This feature safeguards against damage or crushing of foreign objects when the mechanism retracts.

- Mechanical quick-release system: In emergency situations, it enables swift manual disengagement and retraction of the actuator.

- Overload clutch: It disengages the motor when a specific preset load is reached, preventing excessive strain.

These safety measures collectively enhance the reliability and protectiveness of electric actuators, ensuring their efficient and secure operation, not all actuators have them, but this show the available options that can each be integrated into an actuator

To learn more about the safety options of FIRGELLI electric actuators, check out our dedicated article!

5. Synchronizable

Thanks to position sensors, such as Hall sensor’s or Optical sensor's and even potentiometers, two or more electric linear actuators can operate in a synchronized movement. The sensors will provide feedback to the control box, which will adapt the speed of the different motors for perfectly synchronized movement. Synchronization is ideal when the load requires several motors to operate with smooth and stable motion, or the application has in-even loading.

FIRGELLI offers several different position sensors for electric linear actuators:

-

Electric linear actuators can be equipped with various position sensors to enhance functionality and precision:

- Hall effect sensors: These sensors detect the magnetic field, determining the motor's rotation direction and counting the number of motor revolutions. They contribute to accurate positioning control.

- Potentiometer: As a position-retaining sensor, the potentiometer retains the actuator's position even when the power is off. This eliminates the need for a reset, ensuring consistent and reliable positioning.

- Optical sensor: This type of sensor, known as a positional divider, directly correlates the position by reading the voltage output from the potentiometer. It provides precise and immediate feedback on the actuator's position.

By incorporating these sensors, electric actuators can achieve enhanced positional control and accuracy in various applications.

To learn more about FIRGELLI electric actuator sensors, check out our article!

6. Sustainable

Electric linear actuators are engineered for a prolonged service life. Their components are designed to safeguard internal mechanisms and withstand environmental stresses. The motion mechanisms are treated with lubrication, which minimizes friction, lowers operating temperatures, reduces noise and vibration, and prevents premature wear. These measures contribute to increased longevity and durability of the actuators.

To ensure the utmost reliability, FIRGELLI provides additional options for their devices. Many electric linear actuators offer varying levels of IP (Ingress Protection) protection, enabling them to withstand solid and liquid contaminants from the external environment. Certain industrial electric actuators from FIRGELLI can achieve an impressive IP rating of up to IP68, making them suitable for withstanding extreme conditions encountered in industrial settings. This commitment to reliability further enhances the performance and resilience of FIRGELLI electric linear actuators.

For more information, see our article on protection ratings for electric actuators.

7. Compact

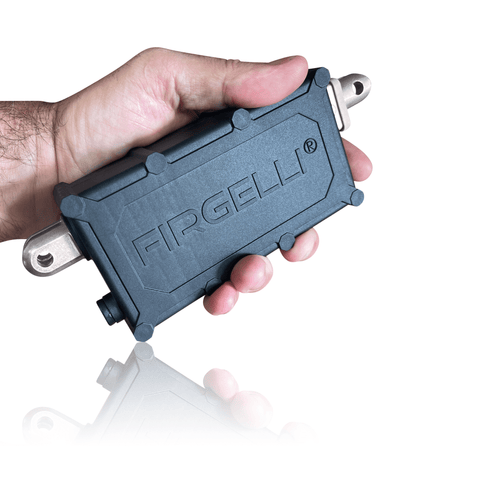

Electric linear actuators possess a compact design that facilitates seamless integration into diverse equipment types. Whether it's large-scale industrial machines, medical equipment, or small furniture, these actuators excel in enabling the creation of complex systems with multiple movements. The compactness of their design empowers product engineers with exceptional versatility, allowing for the integration of multiple electric actuators within a single piece of equipment, even when space for installation is limited. This versatility and space-efficiency make electric linear actuators an ideal choice for a wide range of applications.

8. Maintenance free

Unlike hydraulic or pneumatic actuators that rely on hoses, fluid injection, or air compressors, electric actuators operate without such components. This key distinction positions electric actuators as an excellent alternative that minimizes the need for regular maintenance. Since electric actuators do not have the potential for leaks, they offer a maintenance-free solution that is clean and easy to use. These features prove particularly valuable when the actuator mechanism is located in inaccessible or hard-to-reach areas. By choosing electric actuators, you can enjoy the convenience of a reliable and hassle-free actuation system.

9. Energy efficient

The electric linear actuator consumes little energy compared to hydraulic and pneumatic systems. Most FIRGELLI control boxes have a standby power consumption of less than 0.1 W. And the Actuators themselves consume around 3Amps on average which is significantly less than Hydraulic systems.

10. Ergonomic

Electric actuators exhibit remarkable versatility, enabling a wide range of movement possibilities and facilitating the design of ergonomic and comfortable equipment. Their adaptability to individual requirements enhances accessibility and promotes seamless integration. By leveraging electric actuators, tasks become more manageable, and equipment performance and productivity are enhanced across various activities. Consequently, electric actuators find their application in numerous everyday equipment, transcending industry boundaries and catering to diverse needs with utmost efficiency.

- Industry: industrial and agricultural vehicles, automated equipment, intralogistics transport equipment, window opening and ventilation systems...

- Medical: beds, tables, medical chairs and carts, patient lifts, mobility aids...

- Home furniture: armchairs, recliners, kitchen furniture, desks...

- Professional furniture: sit-stand desks, workstations, laboratory benches, control stations, display units...

Why choose FIRGELLI electric linear actuators? For more than 20 years, FIRGELLI has been supporting its customers in their product development projects with complete turnkey solutions.