What is the difference between a Brushed vs Brushless Motor

Figure 1: Difference between a Brushed vs Brushless motor

Brushed vs Brushless motors, what are the differences

Brushed and brushless DC motors are two distinct types of electric motors. In simple terms, the difference is that brushed motors have electrical contact brushes, which cause the motor to spin. On the other hand, brushless motors rely on electronics rather than brushes to rotate the motor. Another way to describe it is that brushless motors have spinning magnets in the center, while brushed motors have stationary magnets on the outside.

Figure 1 shows the visual difference between the two, however the operation of each is also completely different. The main difference between them is the type of commutation they use:

-

Commutation method:

- Brushed motors use mechanical brushes and a commutator to switch the current direction in the windings, which in turn generates a magnetic field to produce torque and rotate the motor.

- Brushless motors, on the other hand, utilize electronic control and magnetic sensors (e.g., Hall effect sensors) to switch the current direction in the windings without any mechanical contact. This electronic control is often in the form of an external driver or an integrated electronic speed controller (ESC).

-

Efficiency:

- Brushless motors are generally more efficient than brushed motors because they don't have the friction and energy losses associated with brushes and commutators. This leads to better performance, longer runtimes, and reduced energy consumption.

-

Maintenance and lifespan:

- Brushed motors require more maintenance due to the wear and tear on brushes and commutators, which can eventually lead to a decrease in performance and motor failure. Brush replacements are necessary periodically to maintain optimal performance.

- Brushless motors have fewer moving parts and no mechanical contacts, which results in a longer lifespan and reduced maintenance requirements.

-

Noise and vibration:

- Brushless motors usually produce less noise and vibration compared to brushed motors because they don't have brushes or commutators that can cause mechanical noise.

-

Cost and complexity:

- Brushless motors are generally more expensive and complex due to the requirement of electronic control systems for commutation. However, their advantages in terms of efficiency, lifespan, and maintenance often outweigh the initial cost difference.

Brushless Motor Diagram

In the rotor of a brushless motor, permanent magnets are present, while the stator houses the windings. This arrangement is the opposite of the stator and rotor locations in a brushed DC motor. Brushed DC motors initiate rotation when current is supplied to the windings via the commutator and brushes. As the motor spins, the subsequent commutator and brush pairs are energized, directing current flow into different windings and maintaining rotation.Brushless motors achieve commutation without relying on brushes or commutators. Instead, they utilize magnetic pole sensors (such as Hall elements or Hall effect ICs) to identify the permanent magnets' magnetic pole positions. Additionally, drivers are required to guide the current flow through the windings according to the detected magnetic pole positions.

Brushless Motor Principles

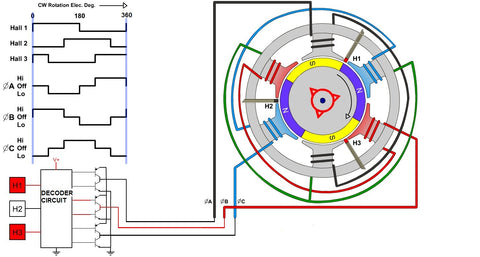

To describe the rotational principles of brushless motors, let's consider a simplified 2-pole, three-phase model as depicted in Figure 2.

The rotor magnets consist of both north and south poles, each having a magnetic pole angle of 180°. Magnetic pole sensors Ha, Hb, and Hc are positioned 120° apart and detect the north pole of the rotor magnets, subsequently producing a signal.

Regarding the stator, the phase-U coil, phase-V coil, and phase-W coil are also placed 120° apart and are offset from the magnetic pole sensors by 60°.

When current flows from the drive circuit to the motor for each phase winding of the stator, a south pole is created on the inner diameter side of the stator. Conversely, when the current flows in the opposite direction, a north pole is generated on the inner diameter side of the stator. Figure 3 illustrates the condition when current flows from phase-U to phase-V.

Figure 3: Simplified brushless motor principle

Control method of a Brushless motor

A brushless motor is controlled by an electronic controller that regulates the power supplied to the motor. The following are the basic steps for controlling a brushless DC motor:- Hall Effect Sensors: Brushless motors use Hall Effect sensors to determine the position of the rotor and provide feedback to the controller.

- Electronic Commutation: The electronic controller uses the information from the Hall Effect sensors to determine the proper sequence of current to be supplied to the stator windings.

- Power MOSFETs or IGBTs: The controller uses power MOSFETs or IGBTs to switch the current supplied to the stator windings.

- PWM Signals: The controller uses Pulse Width Modulation (PWM) signals to regulate the speed and torque of the motor by adjusting the duty cycle of the PWM signals.

- Input Signals: The controller receives input signals from a control source, such as a microcontroller, to set the desired speed and direction of the motor.

The precise method for controlling a brushless motor depends on the specific motor and controller used, but these steps provide a general overview of the process.

How to do you control the speed of a brushless motor

The speed of a brushless DC motor is controlled by adjusting the frequency of the electrical power supplied to the motor. The following are the basic steps for controlling the speed of a brushless motor:

- Electronic Controller: An electronic controller is used to regulate the power supplied to the motor.

- PWM Signals: The controller uses Pulse Width Modulation (PWM) signals to adjust the frequency of the power supplied to the motor. By changing the duty cycle of the PWM signals, the average voltage applied to the motor can be varied, which in turn affects its speed.

- Input Signals: The controller receives input signals from a control source, such as a microcontroller, to set the desired speed of the motor.

- Motor Feedback: In some cases, a feedback mechanism such as a tachometer or encoder may be used to monitor the speed of the motor and provide feedback to the controller, which can then adjust the PWM signals to maintain a constant speed.

Controlling the speed of a brushless DC motor involves adjusting the frequency of the electrical power supplied to the motor using PWM signals and electronic control.

What type of controller do you need for a brushless motor

A brushless DC motor requires an electronic controller, often referred to as an Electronic Speed Controller (ESC), to regulate the power supplied to the motor. The ESC is responsible for the following tasks:

- Monitoring the position of the rotor: Brushless motors use Hall Effect sensors to determine the position of the rotor and provide feedback to the controller.

- Commutation: The controller uses the information from the Hall Effect sensors to determine the proper sequence of current to be supplied to the stator windings.

- Power switching: The controller uses power MOSFETs or IGBTs to switch the current supplied to the stator windings.

- Speed control: The controller uses Pulse Width Modulation (PWM) signals to regulate the speed and torque of the motor by adjusting the duty cycle of the PWM signals.

- Input signals: The controller receives input signals from a control source, such as a microcontroller, to set the desired speed and direction of the motor.

Brushed Motor Diagram

Figure 6: brushed motor structure

A brushed motor is a type of DC electric motor that consists of several key components that work together to convert electrical energy into mechanical energy. The main components of a brushed motor are the rotor, stator, commutator, and brushes as shown in Fig 6. Here's a description of each component and how they contribute to the motor's structure:

- Rotor (Armature): The rotor, also known as the armature, is the rotating part of the brushed motor. It consists of wound coils of wire around an iron core, which creates an electromagnet when current passes through it. The rotor's magnetic field interacts with the stator's magnetic field, generating torque and causing the rotor to spin, driving the motor shaft.

- Stator: The stator is the stationary part of the brushed motor. It houses permanent magnets, typically mounted on the inner surface, providing a fixed magnetic field. The stator's magnetic field interacts with the rotor's magnetic field, creating the necessary torque for rotation.

- Commutator: The commutator is a crucial component of a brushed motor, responsible for switching the current direction in the rotor windings. It is a segmented metal cylinder attached to the rotor, with each segment connected to one end of the rotor windings. As the rotor spins, the commutator rotates along with it, making contact with the brushes.

- Brushes: Brushes are fixed, conductive components that maintain electrical contact with the rotating commutator. They are typically made of carbon or graphite, ensuring low friction and wear. The brushes provide the electrical connection between the power source and the rotor windings through the commutator. As the commutator rotates, the brushes slide over its surface, successively energizing different rotor windings, which in turn causes the rotor's magnetic field to switch and maintain rotation.

A brushed motor consists of a rotor with wound coils, a stator with permanent magnets, a commutator, and brushes. The interaction between the rotor's and stator's magnetic fields generates torque, while the commutator and brushes work together to switch the current in the rotor windings, ensuring continuous rotation.

Principles behind a Brushed motor

DC motors employ coiled wire windings to generate a magnetic field. In a brushed motor, these windings are attached to the rotor, which is free to rotate and drives a shaft. Often, the coils are wrapped around an iron core, although some brushed motors are "coreless," with self-supported windings. The stationary portion of the motor, known as the "stator," uses permanent magnets to establish a fixed magnetic field. These magnets are typically situated on the stator's inner surface, surrounding the rotor. Fig 7 shows greater detail.

To create torque and cause the rotor to spin, the rotor's magnetic field must continuously rotate, interacting with the stator's fixed field through attraction and repulsion. A sliding electrical switch facilitates this rotating field. This switch comprises a commutator, usually a segmented contact mounted on the rotor, and fixed brushes mounted on the stator.

Figure 7: Principles behind a Brushed motor

How to do you control the speed of a brushed motor

The speed of a brushed DC motor can be controlled by adjusting the voltage applied to its terminals. The following are the basic steps for controlling the speed of a brushed DC motor:

- Power Supply: A DC power supply is connected to the motor terminals to provide the electrical power needed to spin the motor.

- Speed Control: To control the speed of the motor, the voltage applied to the motor can be adjusted using a resistor or a pulse width modulation (PWM) signal shown in Fig 8. The lower the voltage applied to the motor, the slower it will rotate. We have written a separate article about Speed controllers here

- Input Signals: The voltage applied to the motor can be controlled by input signals from a control source, such as a microcontroller, to set the desired speed.

- Feedback Control: In some cases, a feedback mechanism such as a tachometer or encoder may be used to monitor the speed of the motor and provide feedback to a controller, which can then adjust the voltage to maintain a constant speed.

Controlling the speed of a brushed DC motor involves adjusting the voltage applied to its terminals, either directly or by using a feedback mechanism to regulate its speed.

Figure 8: Controlling the speed of a brushed motor

In summary, a brushless DC motor requires an Electronic Speed Controller (ESC) to regulate the power supplied to the motor and control its speed and torque.

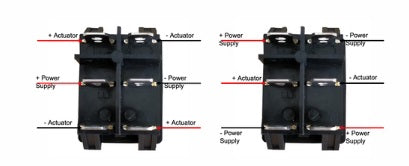

How do you wire a brushless motor to a switch

A typical way to control a brushed motor is to use a Rocker switch. On the bottom of your switch you will see 6 connectors, as seen below, that will line up with the circuit diagram of the DPDT switch above. If the switch is pressed to the forward position, the top and middle connectors will be connected inside the switch; if the switch is pressed to the back position, the bottom and middle connectors will be connected; and if the switch is in the middle position, the switch is open.

Below is a wiring diagram showing 2 brushed motors connected to a switch

A wiring diagram of the back of a rocker switch is shown below

Which is more expensive, a brushed or brushless motor

In general, brushless DC motors are more expensive than brushed DC motors. The cost difference can be attributed to the complexity of the brushless motor system, which requires additional components such as an electronic controller (ESC) and Hall Effect sensors. The ESC and sensors add to the cost of the system, as does the more sophisticated manufacturing process required for brushless motors.

However, despite their higher upfront cost, brushless motors often offer several advantages over brushed motors, including higher efficiency, longer lifespan, and better performance, particularly in high-speed and high-torque applications. As a result, the higher cost of brushless motors can often be offset by their lower operating costs and improved reliability.

In conclusion, the cost of brushed and brushless motors varies depending on the specific application and requirements. Brushless motors are generally much more expensive upfront, but they may offer longer life-span and greater efficiency. Brushed motors are ideal for most day to day type applications, and for people with little to no electrical expierience. You may find brushless motors used for electric cars and other systems where very long lifespan is required (many decades), but outside of this, you will find that Brushed motors make up 95% of the motor market.

Check out our Linear Actuators here