Eletrical reclining beds - A guide to the technology used inside them

Electric reclining beds are a type of bed that can be adjusted to different positions, including a fully reclined position. These beds are often used by people with back pain or other health conditions that make it difficult to sleep in a flat position. Electric reclining beds can also be used by people who simply want a more comfortable bed to sleep in.

Motion Control

The motion control system of an electric reclining bed is what allows the bed to be adjusted into different positions. This system is typically made up of a number of actuators, which are motors that move the different parts of the bed. The actuators are controlled by a computer, which receives input from a remote control or a sensor that detects the user's position.

The motion control system of an electric reclining bed is a complex system that requires a lot of engineering and design. The actuators must be able to move the bed smoothly and without any jerks or vibrations. They must also be able to handle the weight of the bed and the user.

The computer that controls the motion control system must be able to process the input from the remote control or the sensor and then send the correct signals to the actuators. It must also be able to monitor the system for any problems and take corrective action if necessary.

Actuators

The actuators are the motors that move the different parts of an electric reclining bed. They are typically made up of a motor, a gearbox, and a linkage. The motor provides the power to move the linkage, which in turn moves the different parts of the bed.

The gearbox is used to reduce the speed of the motor and increase the torque. This is necessary because the motor is not strong enough to move the bed directly. The linkage is used to transmit the power from the motor to the different parts of the bed.

Forces

There are a number of forces involved in the motion of an electric reclining bed. These forces include:

- Gravity: The force of gravity pulls the bed down.

- Friction: The force of friction between the bed and the floor prevents the bed from sliding.

- Spring force: The spring force pushes the bed back up when it is compressed.

- Motor force: The motor force moves the bed.

Design

The design of an electric reclining bed is a complex process that requires a lot of engineering and design. The bed must be designed to be comfortable, safe, and reliable. It must also be designed to meet the needs of the user.

The design process typically starts with a brainstorming session. During this session, the engineers and designers come up with ideas for the bed. They consider the different features that the bed should have and the different ways that it should be used.

Once they have a few ideas, they start to develop prototypes. These prototypes are used to test the different features and to make sure that the bed is comfortable and safe.

After the prototypes are developed, the final design is created. This design is used to manufacture the bed.

Building

The building of an electric reclining bed is a complex process that requires a lot of engineering and manufacturing. The bed must be built to be safe and reliable. It must also be built to meet the needs of the user.

The building process typically starts with the manufacturing of the parts. The parts are then assembled into the bed. The bed is then tested to make sure that it is safe and reliable.

Once the bed is built, it is shipped to the customer. The customer then assembles the bed and enjoys their new electric reclining bed.

The Ideal Actuator for Electric Reclining Beds

The ideal actuator for an electric reclining bed is one that is powerful, efficient, and reliable. It should also be able to move the bed smoothly and without any jerks or vibrations.

Some of the ideal actuators for electric reclining beds include:

- Electric motors: Electric motors are a good choice for actuators in electric reclining beds because they are powerful and efficient. They can also be controlled easily by a computer.

- Servo motors: Servo motors are another good choice for actuators in electric reclining beds. They are accurate and can move the bed smoothly. They are also more expensive than electric motors.

- Hydraulic cylinders: Hydraulic cylinders are a good choice for actuators in electric reclining beds that need to move heavy loads. They are powerful and can move large amounts of weight.

- Pneumatic cylinders: Pneumatic cylinders are another good choice for actuators in electric reclining beds that need to move heavy loads. They are powered by compressed air and are less expensive than hydraulic cylinders.

How to Build an Electric Reclining Bed

Electric reclining beds are a popular choice for people who want a comfortable and relaxing place to sleep. They can also be a good option for people with back pain or other health conditions that make it difficult to sleep in a flat position.

Building an electric reclining bed can be a challenging project, but it is also a rewarding one. With a little planning and effort, you can build a bed that is both comfortable and stylish.

The Ideal Actuators for Electric Reclining Beds

The ideal actuators for an electric reclining bed are ones that are powerful, efficient, and reliable. They should also be able to move the bed smoothly and without any jerks or vibrations.

Some of the ideal actuators for electric reclining beds include:

- Electric motors: Electric motors are a good choice for actuators in electric reclining beds because they are powerful and efficient. They can also be controlled easily by a computer.

- Servo motors: Servo motors are another good choice for actuators in electric reclining beds. They are accurate and can move the bed smoothly. They are also more expensive than electric motors.

- Hydraulic cylinders: Hydraulic cylinders are a good choice for actuators in electric reclining beds that need to move heavy loads. They are powerful and can move large amounts of weight.

- Pneumatic cylinders: Pneumatic cylinders are another good choice for actuators in electric reclining beds that need to move heavy loads. They are powered by compressed air and are less expensive than hydraulic cylinders.

How to Calculate What Actuator to Use

To calculate the force and actuator specifications required to lift a reclining bed, you need to consider the weight of the bed, the angle of inclination, and the desired speed of lifting. Here is a step-by-step guide to help you with the calculations:

- Determine the weight of the bed: First, you need to know the total weight of the bed, including the mattress and any additional bedding or accessories. This weight will be used to calculate the force required to lift the bed.

- Calculate the force required: When lifting a reclining bed, only a portion of the total weight needs to be lifted, depending on the angle of inclination. To determine this force, you can use the following formula:

Force = Total Weight × sin(Angle)

where:

- Force is the force required to lift the bed (in newtons)

- Total Weight is the combined weight of the bed, mattress, and accessories (in newtons; 1 kg ≈ 9.81 N)

- Angle is the desired angle of inclination from the horizontal position (in degrees)

Make sure to convert the angle to radians before calculating the sine (1 degree ≈ 0.0174533 radians).

- Consider the safety factor: To ensure reliable operation and account for potential variations in weight or friction, it's recommended to apply a safety factor to the calculated force. A common safety factor is 1.5 to 2 times the calculated force.

Adjusted Force = Force × Safety Factor

- Select the actuator: Choose a linear actuator with a force rating equal to or greater than the adjusted force calculated in step 3. Also, consider the actuator's speed, stroke length, and other specifications to ensure compatibility with your bed design.

- Additional calculations: If you want to determine the power and current requirements for the actuator, refer to the actuator's datasheet for specific values. You might also want to calculate the torque required for the motor driving the actuator based on the force and the mechanical advantage of the lifting mechanism.

These calculations will help you select the appropriate actuator and motor for lifting a reclining bed. Be sure to consult the actuator and motor manufacturer's specifications and guidelines to ensure safe and reliable operation.

Reclining Bed Force Calculator

Results

Force: 0 lbs

Adjusted Force: 0 lbs

How to Build an Electric Reclining Bed

The following are the steps involved in building an electric reclining bed:

- Choose the appropriate actuators.

- Calculate the required force, power, and speed.

- Build the frame of the bed.

- Install the actuators.

- Install the control system.

- Test the bed.

Building the Frame of the Bed

The frame of the bed is the foundation on which everything else is built. It is made of wood or metal and should be strong enough to support the weight of the bed and the actuators.

The frame should be rectangular in shape and should have a series of crossbeams that support the weight of the bed. The crossbeams should be spaced evenly and should be attached to the frame with screws or nails.

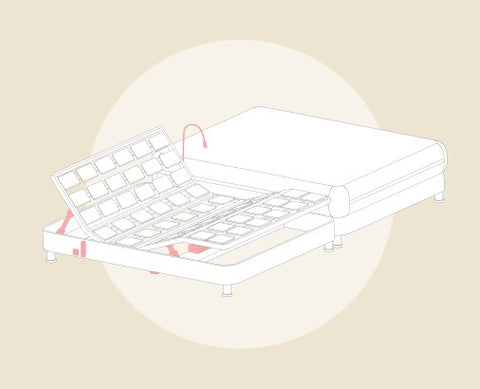

Installing the Actuators

The actuators are the motors that move the bed. They should be installed in a way that allows them to move the bed smoothly and without any jerks or vibrations.

The actuators should be mounted on the frame of the bed and should be attached with screws or nails. The actuators should also be connected to the control system.

Installing the Control System

The control system is the brains of the bed. It is responsible for controlling the actuators and for making sure that the bed moves smoothly and without any problems.

The control system should be installed in a central location in the bed. It should also be connected to the actuators and to the power supply.

Testing the Bed

Once the bed is built, it should be tested to make sure that it works properly. The bed should be raised and lowered several times to make sure that it moves smoothly and without any problems.

The bed should also be tested to make sure that it is comfortable. The bed should be reclined to a comfortable position and should be slept in for a few minutes to make sure that it is comfortable.