Behind What Makes Robotics Real

The robotics revolution isn't just about AI; it’s about physical interaction with the world. FIRGELLI provides the reliable, precise infrastructure that turns digital commands into physical movement. We are the picks-and-shovels of the robotics industry, providing the essential linear motion components that engineers trust to build functional, scalable, and durable robots, regardless of hype cycles

Why Robots Need Linear Actuators

While rotary motors are fundamental to robotics, mimicking biological movement—particularly in humanoids and sophisticated service robots—often requires direct linear motion.

Nature doesn't rely solely on rotation at the joint. Muscles pull linearly to create articulation. To achieve realistic, compact, and high-torque movement in fingers, arms, and torsos, relying only on rotary servos with complex, bulky gearing systems is inefficient. FIRGELLI linear actuators provide direct push/pull forces, allowing engineers to design push-rod mechanisms and tendon-driven systems that fit into tight envelopes where rotary motors simply cannot. They are essential for creating bio-mimetic motion, locking positions without power, and providing high force density in compact spaces.

FIRGELLI Robotics Actuator Categories

We supply a diverse range of linear motion solutions scaled for different robotic Nik subsystems, from delicate grippers to load-bearing chassis components.

Micro Actuators (Hands, Fingers, End-Effectors)

For applications where space is at an absolute premium and fine control is paramount.

• Micro Pen Actuators: Finger-sized linear actuators designed for incredibly tight spaces like robotic phalanges or delicate gripping mechanisms.

• Micro Utility Actuators (Coming Soon): The next evolution in compact power, offering versatile mounting options for small-scale robotic articulation.

Compact Actuators (Grippers, Assist Joints, Neck Motion)

Mid-range solutions offering a balance of speed, force, and compact footprint. Ideal for actuating secondary joints, camera gimbals, or assisting rotary primary joints.

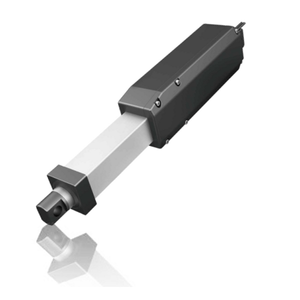

High-Force Actuators (Knees, Torso, Load Paths)

Heavy-duty actuators designed to handle the structural loads of service robots and humanoids. These are essential for knee joints, waist actuation, and center-of-gravity shifting mechanisms.

Control Feedback: The Precision You Need

In robotics, moving is only half the battle. Knowing exactly where you are is critical. Open-loop systems are insufficient for autonomous operation.

FIRGELLI understands that closed-loop control is non-negotiable for advanced robotics. Our key robotics actuator lines feature integrated, high-precision Hall Effect sensors.

• Fine Motion Control: The Hall sensors provide precise positional feedback to your controller, allowing for micro-adjustments, smooth acceleration curves, and accurate repeatability.

• Controller Compatibility: Our feedback systems are designed to integrate seamlessly with standard robotics control architecture, including ROS (Robot Operating System) based controllers, Arduino, Raspberry Pi, and industrial PLCs.

Robotics Use Cases

FIRGELLI motion systems are currently deployed across diverse sectors of the robotics landscape.

• Humanoid Robots: Providing the "musculature" for realistic limb articulation, hand gesturing, and stabilization.

• Service & Delivery Robots: Actuating lids, locking mechanisms, variable height adjustments, and interaction arms.

• Medical & Lab Robotics: utilized in surgical assist devices, automated rehabilitation equipment, and precise laboratory automation tasks.

• Research & University R&D: The trusted standard for reliable, documented test platforms in academic and corporate research labs globally.

Why Engineers Choose FIRGELLI

Building robots is hard. Your supply chain shouldn't make it harder. FIRGELLI positions itself not just as a vendor, but as a long-term infrastructure partner for your engineering team.

• In-House Testing & Data: We don't just ship parts; we understand their limits. We provide the necessary data so you can model your robot's performance accurately before prototyping.

• Documentation: Clear specs, 3D models, and integration guides to speed up your design cycle.

• Global Supply Chain: We have the logistics infrastructure to support you from the prototyping phase to mass production scaling.

• Long Product Lifecycles: Industrial and service robots need to last for years. FIRGELLI is committed to supporting our core product lines for the long haul, ensuring you aren't left redesigning your robot due to obsolete components.