How FIRGELLI Micro Actuators Are Powering the Next Generation of Humanoid Robotics

From Physical Intelligence to Human-Scale Motion

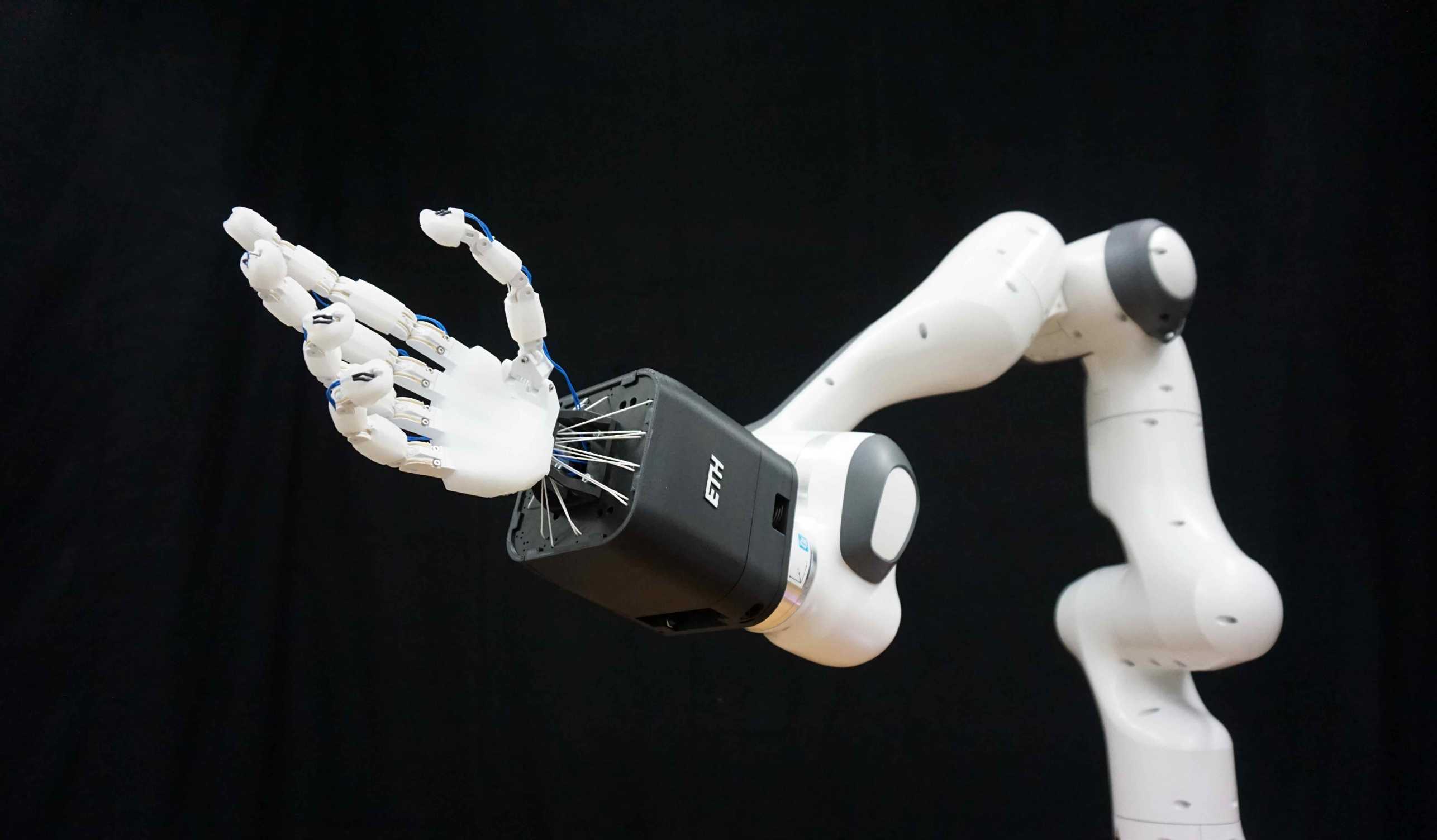

Humanoid robotics is no longer speculative science fiction — it is rapidly becoming the next frontier of Physical Intelligence.

While large language models and vision systems now rival human-level cognition in constrained tasks, the limiting factor in humanoid robots is no longer the mind — it is the body. The challenge facing roboticists today is brutally practical:

How do you fit 25–30 degrees of freedom into a human-sized frame without creating a heavy, power-hungry, mechanically unstable machine?

The answer is not bigger motors or more complex gearboxes.

The answer is micro-actuation.

FIRGELLI Micro Linear Actuators provide the force density, precision feedback, and tendon-like form factors required to replicate biological motion at human scale — making them a foundational building block for modern humanoid robots.

1. What Are Micro Actuators in Humanoid Robotics?

In humanoid robotics, a micro actuator is not defined solely by physical size. It is defined by usable mechanical work delivered within an extremely constrained volume.

The FIRGELLI FA-BS16 micro linear actuator series exemplifies this category.

With a 16 mm (0.62”) diameter inline body, these actuators avoid the packaging penalties of rotary servos and stepper motors that require perpendicular gear trains or bulky housings. Instead, they deliver direct linear motion in a form factor small enough to integrate into robotic forearms, hands, ankles, and compact joint assemblies.

With a 16 mm (0.62”) diameter inline body, these actuators avoid the packaging penalties of rotary servos and stepper motors that require perpendicular gear trains or bulky housings. Instead, they deliver direct linear motion in a form factor small enough to integrate into robotic forearms, hands, ankles, and compact joint assemblies.Key Characteristics That Matter in Robotics

-

Compact Geometry

Retracted lengths from 140 mm to 220 mm allow dense internal packing within limbs. -

High Force Density

Despite weighing as little as 49 g (1.7 oz), the series delivers up to 100 N (22 lb) of linear force. -

Built-In Feedback

Integrated Hall Effect sensors enable closed-loop position control — a prerequisite for smooth, human-like motion.

This combination is what makes micro actuators viable as robotic muscles, not just miniature motors.

2. Replicating Biological Motion with Linear Actuation

Human joints are not driven by rotary motors at the pivot. They are driven by linear muscles pulling through tendons.

To achieve natural gait, balance, and dexterity, humanoid robots must adopt the same architectural principle.

FIRGELLI micro actuators enable this by allowing engineers to:

-

Place actuators away from the joint

-

Transmit force through linkages or cable-tendon systems

-

Minimize mass at the extremity (hands, feet, wrists)

Reducing distal inertia dramatically improves:

-

Acceleration and deceleration smoothness

-

Energy efficiency

-

Stability during dynamic motion

This is why tendon-driven architectures dominate advanced humanoid designs.

3. Proprioception: Why Feedback Resolution Matters

True biological motion requires proprioception — awareness of limb position, speed, and resistance.

FIRGELLI micro actuators integrate dual Hall Effect sensors with a 90-degree phase offset, enabling high-resolution motion tracking.

Feedback Performance

-

Resolution:

Up to 1,143 pulses per inch (≈45 pulses/mm) on the 100 N model -

Control Quality:

High pulse density enables smooth PID loops without the oscillation or “jitter” seen in low-resolution servo systems

This level of feedback allows humanoid robots to:

-

Perform delicate manipulation

-

Maintain stable posture under load

-

Adapt motion in real time

4. Solving Core Humanoid Robotics Constraints

Weight and Inertia: The Battle Against Gravity In humanoid design, distal mass (weight at the ends of limbs) is the enemy. Heavy actuators in the hand or foot create a "pendulum effect," requiring massive torque at the shoulder or hip just to move the limb. FIRGELLI actuators address this through material science. By utilizing Aluminum T6063 for the housing and Stainless Steel 304 for the expansion rod, we achieve a high stiffness-to-weight ratio.

-

Result: A total unit weight between 49 g and 81 g.

-

Engineering Impact: This ultra-light footprint allows actuators to be mounted directly in the forearm or shin, transmitting force via tendons, which drastically reduces the moment of inertia for the entire limb.

Power Efficiency and Thermal Management Battery density is a major bottleneck for mobile robots. Traditional DC servos must constantly "fight" gravity, drawing continuous current just to hold a static pose. This not only drains the battery but generates waste heat that can degrade motor performance over time. The FA-BS16 series solves this with a precision-engineered ACME screw drive.

-

Self-Locking Physics: The geometry of the ACME thread prevents back-driving. This means the actuator can hold a static load of up to 140 N (33 lb) with zero power consumption.

-

Thermal advantage: With a maximum current draw of only 0.3 A at 12 V (even at full load), these actuators run cool. This eliminates the need for bulky heatsinks or active cooling fans inside the robot's limbs, saving even more space and weight.

5. Matching Actuator Performance to Robotic Function

Biological muscles are not uniform; fast-twitch fibers move eyes, while slow-twitch fibers support posture. FIRGELLI allows you to replicate this specialization with three distinct gearing options, ensuring every joint has the optimal force-velocity profile.

Application-Specific Configurations:

-

The "Saccadic" Motion (Eyes & Eyelids):

-

Model: 20 N (4.5 lb) force / 15 mm/s speed.

-

Why: Robotic eyes require rapid, low-force movements to mimic human "saccades" (quick, simultaneous movements). The high speed of this model ensures blinking and tracking feel natural and responsive, not robotic and sluggish.

-

-

The "Dexterous" Grip (Fingers & Thumbs):

-

Model: 50 N (11 lb) force / 5.8 mm/s speed.

-

Why: This offers the "Goldilocks" balance. It provides enough speed for fluid hand gestures but retains enough mechanical advantage to crush a soda can or grip a heavy tool securely.

-

-

The "Structural" Lock (Knees & Latches):

-

Model: 100 N (22 lb) force / 3 mm/s speed.

-

Why: For locking joints (like a knee in a standing position) or actuating heavy latches, speed is secondary to raw holding power. This gearing maximizes torque, ensuring stability under load.

-

6. Integration Tips for Robotics Engineers

Control & Feedback: The Nervous System The built-in Hall Effect sensors are the "nerves" of the actuator. Operating at a standard 5V logic level, they consume negligible power while providing critical telemetry.

-

Pulse Counting Logic: As the motor spins, the Hall sensors generate a square wave pulse train. A microcontroller (like an Arduino or ESP32) simply needs to count these edges (rising or falling) to track position.

-

Resolution is Control: With up to 1143 pulses per inch (on the 22lb model), the feedback is granular enough to detect sub-millimeter movements. This high density allows your PID control loop to make micro-adjustments hundreds of times per second, resulting in smooth, organic motion rather than jerky "stepped" movement.

Mounting and Mechanical Interface

-

Freedom of Movement: The actuators feature Plastic O-type rod ends with 3 mm holes. This clevis-style mount allows the actuator to pivot slightly as it extends, compensating for the non-linear arc of motion found in finger knuckles and elbow joints.

-

Prototyping Friendly: The dimensions are compatible with standard M3 hardware and easily integrate into 3D-printed chassis, accelerating the "design-build-test" cycle.

Synchronous Motion In complex joints (like a wrist moving in two axes), actuators must move in perfect unison. Thanks to the tight manufacturing tolerances and a positional repeatability of ±0.1 mm, software synchronization is reliable. You can slave multiple actuators together in code, ensuring they extend and retract at the exact same rate to prevent mechanical binding.

7. The Future: AI-Driven Actuation

As Artificial Intelligence moves from "Chatbots" to "Physical Bots," the hardware must provide data that the AI can understand. FIRGELLI micro actuators are "AI-Ready" edge devices.

-

Proprioception: By monitoring the Hall sensor feedback, the AI knows exactly where every limb is without needing external cameras.

-

Force Inference: Because the current draw is linearly related to force, an AI can infer "grip pressure" simply by reading the current sensor. If the actuator stops moving (Hall pulses stop) but current rises, the AI knows it has grasped an object.

-

Adaptive Behavior: This telemetry enables Sensor-Driven Adaptive Control. The robot can learn to handle a fragile egg differently than a hammer, adjusting its grip strength in real-time based on the feedback loop from the actuator's own internal sensors.