Fundamentals of Electric Linear Actuators: Verbetering van presisie en beheer in robotika, ingenieurswese en verder

Elektriese lineêre aandrywers (ELA's) is 'n noodsaaklike komponent in die moderne werktuigkit van ingenieurs, robotiste, industriële ontwerpers en die DIY -entoesias. In staat om draaibeweging na lineêre krag te omskep, is Elas veelsydig, presies en kan gevind word in 'n magdom toepassings, van hoë-tegnologie robotarms tot die opheffingsmeganismes in u gunsteling meubelstuk. Hierdie diepgaande ondersoek sal die verwikkeldhede, voordele en toekomstige trajekte van ELA-tegnologie ontrafel, wat u bemagtig om ingeligte besluite te neem en nuwe moontlikhede in u projekte te ontsluit.

Begrip van elektriese lineêre aktuators

'N Elektriese lineêre aktuator is 'n toestel wat reguitlynbeweging deur elektriese energie skep. In vergelyking met hul hidrouliese en pneumatiese eweknieë, bied elektriese aktuators skoner, stil, meer beheerbare beweging. Daar is verskillende soorte Elas, waaronder balskroef, gordel-aangedrewe en staafstyl-elektriese aktuators, elk met hul voordele en toepassings.

Die soorte elektriese lineêre aktueerders

Staaf lineêre aktuators: kompak en robuust

Rod-styl aktuators is miskien die mees herkenbare. Dit bestaan uit 'n staaf wat in 'n lineêre beweging strek en terugtrek. Dit word in baie toepassings van sommige gebruik wat slegs 'n eenvoudige beweging van A na B benodig, maar ook hoër presisie -toepassings wat 'n hoë mate van akkuraatheid en stabiliteit benodig, soos in mediese toestelle en monteerlynmasjiene.

Gordelgedrewe aktueerders: spoed en veelsydigheid

Bordelgedrewe aktueerders gebruik 'n gordel- en katrolstelsel om lineêre beweging te skep. Hierdie ontwerp bied vinnige beweging en is 'n gewilde keuse in stelsels, verpakkingsapparatuur en materiaalhantering. Dit is ideaal vir baie hoëspoedprojekte, maar die snelheidshandel is af met geweld, so tipies gordelaangedrewe aktuators bied nie veel krag in vergelyking met 'n loodskroefgedrewe aktuator nie.

Die keuse van die regte aktuator vir u aansoek

Die keuse van die ideale aktuator vereis 'n deeglike begrip van die vereistes van u projek. As u 'n lineêre aktuator oorweeg, sluit sleutelparameters om te ontleed spoed, krag en beroerte lengte.

Navigasie van die snelheidsmagspektrum

Actuator's benodig dikwels 'n uitruil tussen spoed en krag. Hoër krag kan beteken dat die snelheid opoffer en omgekeerd. Die begrip van hierdie verhouding is van kritieke belang in die keuse van 'n aktuator wat die behoeftes van u toepassing die beste kan voorsien. Ons het 'n gedetailleerde artikel hieroor geskryf in 'n pos genaamd "Lineêre aktuators 101" In hierdie artikel gaan ons baie diepte oor hierdie inruil plus nog baie meer.

Die bepaling van die toepaslike streellengte

Die lengte van die beroerte, of die afstand wat 'n aktuator van einde tot einde kan beweeg, is 'n ander kritieke aspek. Langer beroertes benodig dikwels langer aktuators en kan die looptye beïnvloed, dus maak seker dat u die beroerte ooreenstem met u spesifieke ruimtelike en tydsberekeningvereistes.

Beheer van die mosie: opsies en oorwegings

Die metode van beheer is net so belangrik soos die aktuator self. Van eenvoudige op-af-skakelaaropsies tot meer gesofistikeerde beheer met terugvoerstelsels, moet die vlak van beheer geharmoniseer word met die akkuraatheid en herhaalbaarheid wat u aansoek benodig.

Bemeestering van die beheer: taktiek vir presisie

Die beheer van 'n elektriese lineêre aktuator met presisie is uiters belangrik, veral in toepassings waar akkuraatheid nie onderhandelbaar is nie. Hierdie segment gee 'n uiteensetting van benaderings om lineêre aktueerders te beheer, wat wissel van basiese tot gevorderde.

Die eenvoud van 'n skakelaar

Basiese beheerstelsels maak staat op skakelaars vir opdraginette, wat dien as die basis vir beide hand- en outomatiese stelsels. As u die polariteit van die motor met 'n eenvoudige skakelaar omkeer, kan die aktuator van rigting verander, wat 'n koste-effektiewe en eenvoudige beheermetode bied.

Vir meer gesofistikeerde behoeftes, Terugvoering Actuators word vereis, met behulp van sensors soos Hall Effect -sensors of enkodeerders om die beheerstelsel inligting oor die aktuator se posisie te gee. Met hierdie gegewens in die hand, kan die beheerder die gedrag van die aktuator fyn aanpas, limiete instel, posisies rig en die snelheid met akkuraatheid moduleer.

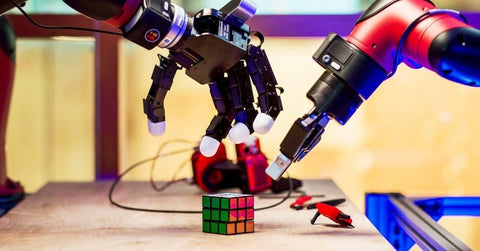

Werp lig op aktuatoraansoeke

Die gebruiksgevalle vir elektriese lineêre aktueerders is uiteenlopend en uitgebrei, wat 'n breë spektrum van nywerhede en produkte raak. Van die verbetering van outomatisering in die huis tot die bemagtiging van presisie -ingenieursprojekte, is elektriese lineêre aktueerders die kern van innovasies regoor die wêreld.

'N verskeidenheid nywerhede onder sy invloed

Die sterkte, akkuraatheid en veelsydigheid van aktuators sorg vir verskillende sektore, waaronder lug- en ruimtevaart, motor, vervaardiging en meer. Dit is 'n belangrike rol in toepassings soos produksielyntransportbande, aanpassings van vliegtuie -flap, en motorfietsbeheer van die versnelling, wat hul aanpasbaarheid toon.

Werklike aktuatoroplossings

Buiten die winkelvloer, word aktuators gevind in tuisautomatisering, landboutoerusting en selfs bewegingsimulators. Hulle het lessenaars aan die gang, pas sonpanele aan en pas die fokus op fotografie-toerusting fokus, wat hul huishoudelike en verbruikersgerigte nut demonstreer.

Voordele van die keuse van elektriese lineêre aktuators

Elektriese lineêre aktueerders bied verskeie voordele bo hul hidrouliese en pneumatiese eweknieë. Hierdie voordele sluit in presisie, energie -doeltreffendheid en 'n meer kompakte en hanteerbare grootte, wat dit in baie scenario's 'n aantreklike keuse maak.

Presisie en herhaalbaarheid: die aktuatorvoordeel

Aktuators bied ongeëwenaarde presisie en herhaalbaarheid, wat dit ideaal maak vir toepassings wat presiese standaarde eis.

Energie -doeltreffendheid en omgewingsvriendelikheid

In vergelyking met hidrouliese stelsels, is aktueerders meer energiedoeltreffend en omgewingsvriendelik, sonder hidrouliese vloeistowwe om weg te doen en minder energie wat benodig word om te werk.

Kompak en skoon ontwerp

Die kompakte ontwerp en 'n gebrek aan vloeistoflekkasies maak elektriese aktuators makliker om in te pak en te onderhou, terwyl dit ook 'n skoner voorkoms en omgewing bied om binne te werk.

Kies verstandig: aktuator seleksie en onderhoud

By die keuse en instandhouding van elektriese lineêre aandrywers is daar verskillende faktore wat u moet oorweeg om optimale werkverrigting en lang lewe te verseker. Behoorlike seleksie en versorging kan die opbrengs op u belegging maksimeer en kritieke mislukkings voorkom.

Die keuse van die regte aktuator: faktore wat u moet oorweeg

As u 'n elektriese lineêre aktuator kies, dink aan die omgewingsfaktore, soos temperatuur en stof, wat die werkverrigting, sowel as die werksiklus en laskenmerke van u toepassing kan beïnvloed.

Installasie en onderhoud Beste praktyke

Gereelde onderhoud, insluitend smering en inspeksie van sleutelkomponente, kan skade voorkom en die gladde werking verseker. Die beste praktyke van die installasie, soos behoorlike montering en belyning, is ook deurslaggewend vir die aktuator se prestasie en lewensduur.

Die konstante evolusie van lineêre aktueerders

Die veld van elektriese lineêre aktueerders is dinamies, met deurlopende innovasie en bevordering in tegnologie. As u op die hoogte bly van die nuutste neigings, kan dit insigte bied in die toekoms van aktuators en die moontlike implikasies vir u projekte en nywerhede.

Die opkoms van slim aktuators

Slim aktueerders met geïntegreerde beheerstelsels en draadlose konnektiwiteit word meer algemeen, en bied afstandmonitering en gevorderde beheerfunksies.

Sien uit: toekomstige neigings en implikasies

Namate tegnologie vorder, kan ons verwag om verhoogde miniatuur, verbeterde materiale en meer intelligente beheerstelsels te sien, wat lei tot aktuators wat selfs meer bekwaam, veelsydig en gebruikersvriendelik is. Die toepassings sal uitbrei, met moontlike implikasies vir alles van ruimte -eksplorasie tot ons daaglikse lewens.

Gevolgtrekking: omhels die krag van elektriese lineêre aktueerders

Elektriese lineêre aktueerders verteenwoordig die nexus van presisie, beheer en tegnologiese innovasie. Deur hul fundamentele beginsels te verstaan en op hoogte te bly van die nuutste ontwikkelings, kan u die volle potensiaal van ELA's in u projekte benut. Of u nou die meganismes van die toekoms bedink of bestaande stelsels verbeter, die ywerige toepassing van ELA's kan dien as 'n kragtige katalisator vir u pogings.

Begin met die reis om die volle potensiaal van elektriese lineêre aktueerders in u werk te ontketen. Van die keuse van die regte aktuator vir u aansoek om die beheer daarvan te bemeester en om behoorlike onderhoud te verseker, is die diepte en breedte van hul nut net so uitgebreid soos u verbeelding. Verken die wêreld van elektriese lineêre aktueerders en sien hoe hulle die grense van presisie, beheer en meganisasie herdefinieer.